Foam Fabrication: Bringing Shape and Protection to Your Needs

Crafting Custom Foam Solutions to Match Your Needs

Foam, a ubiquitous material known for its lightness and versatility, can be transformed into a multitude of shapes and functionalities through the power of foam fabrication. We don’t just sell foam; we transform it into innovative solutions through our comprehensive foam fabrication services.

From foam packaging products to assembled custom foam items, we offer unique fabrication services to meet your specific requirements. Explore our capabilities in working with various foam types, including reticulated polyurethane foam, open-cell foam, and closed-cell foam. Trust CustomFoamParts for top-notch fabrication specialties that elevate your projects to new heights.

What is Foam Fabrication?

Foam fabrication goes beyond simply cutting foam sheets. It’s a comprehensive process that transforms raw foam materials into a wide range of products. This process can involve:

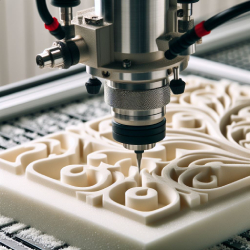

Cutting: Utilizing precise CNC machines or water jets to achieve intricate shapes and dimensions.

Lamination: Bonding multiple foam layers together to create varying densities and functionalities.

Forming: Employing heat or pressure to mold foam into specific shapes for applications like packaging inserts or furniture components.

Finishing: Adding surface treatments like coatings or laminates to enhance aesthetics, fire resistance, or other properties.

We Partner with You

We understand that every project has unique requirements. Our team of skilled technicians and experienced designers will work closely with you to Identify your needs and goals. Recommend the most suitable foam type and fabrication techniques. Develop a cost-effective and efficient production plan. Deliver high-quality foam products that meet your exact specifications.

Let’s discuss how our custom foam fabrication services can transform your projects.

Our Comprehensive Foam Fabrication Services Covers

Whether you require specialty foams, natural fibers, or plastics, our advanced technology empowers us to engineer a wide spectrum of custom foam parts that precisely align with your unique specifications.

Custom Foam Cutting:

Precision cutting of foam materials to create custom shapes and sizes for diverse applications.

CNC Foam Routing:

Employing computer numerical control (CNC) technology for intricate and precise shaping of foam materials during fabrication.

Die-Cutting:

Using specialized dies for cutting foam into specific shapes, ideal for large-scale production with consistent outcomes.

Foam Laminating:

Expert bonding of multiple layers of foam to create thicker and more durable materials for specialized purposes.

Foam Molding:

Shaping foam materials into desired forms using molds, allowing complex and customized designs to be produced.

Waterjet Cutting:

Employing high-pressure waterjets for the precise cutting of foam materials, perfect for intricate and detailed designs.

Decades of Expertise in Custom Foam Fabrication Services

With over 40 years of experience, CustomFoamParts stands as a beacon of excellence in delivering unparalleled custom foam product fabrication services. Our commitment to excellence is reflected in our extensive experience in providing top-notch custom foam fabrication services. Situated in our expansive 100,000-plus square foot facility in Houston, Texas, trust in our decades-long experience to elevate your foam requirements.

Expanding Possibilities with Custom Foam Fabrication Services

Our range of custom foam services extends beyond the ordinary. From assembly to logistics, we offer a comprehensive suite of services, including Convoluting, Contour Cutting, Design and Testing, Dimensional Cutting, Heat Sealing, Hot Wire Cutting, Kitting, Lamination, Rapid Response Warehousing, Saw Cutting, Skiving, and Slitting. The possibilities of foam fabrication are endless. Here are some examples of its diverse applications:

- Protective Packaging: Custom foam inserts for electronics, medical devices, and other delicate products.

- Furniture Components: Padding, seating elements, and sound dampening materials.

- Construction: Expansion joints, insulation panels, and acoustic barriers.

- Consumer Goods: Sporting goods padding, toy components, and appliance components.