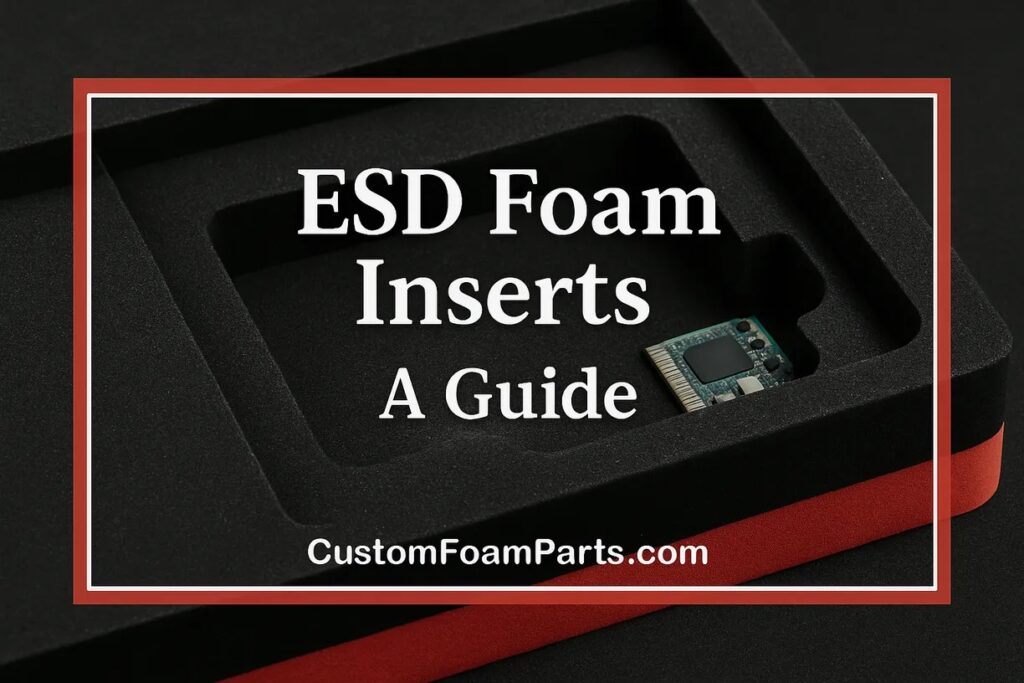

When it comes to safeguarding fragile items during shipping or storage, custom foam inserts generally provide superior protection compared to bubble wrap thanks to their tailored fit, shock absorption, and durability. Bubble wrap still works for lightweight or temporary packaging, but for maximum safety, efficiency, and brand presentation, Custom Foam Parts recommends custom foam inserts. This guide explains why, using real-world examples, industry insights, and sustainability factors to help you make the best choice.

Understanding the Basics of Protective Packaging

Before deciding, it’s important to know exactly what you’re comparing.

What Are Custom Foam Inserts?

Custom foam inserts are precision-engineered foam components cut to the exact dimensions of your product. At Custom Foam Parts, these inserts are available in PE foam, PU foam, and EVA foam, each offering a specific level of cushioning, moisture resistance, and presentation appeal.

Key Benefits:

- Exact fit for each item, reducing movement

- Dense, shock-absorbing material that prevents breakage

- Multiple foam types for different protection levels

- Customizable colors, textures, and branding

What Is Bubble Wrap?

Bubble wrap consists of polyethylene sheets filled with air bubbles that create cushioning around products. It’s typically sold in rolls and cut to fit each shipment.

Key Benefits:

- Lightweight for lower shipping costs

- Easy to wrap around irregular shapes

- Widely available and inexpensive

- Fun to pop (but that’s not great for protection!)

Comparing Protection Levels

The primary purpose of any packaging is damage prevention. Here’s how each performs under real-world conditions:

Custom Foam Inserts

Shock Absorption

Offer uniform cushioning that absorbs both direct and indirect impacts.Movement Restriction

Hold items firmly in place with no shifting during transport.Long-Term Storage:

Retain shape and performance over months or years.

Bubble Wrap

Shock Absorption

Handles light bumps well but can flatten under sustained pressure.Movement Restriction

Even with multiple layers, items can still move inside the box.Long-Term Storage

Air slowly escapes from bubbles, reducing protection.

Overall Winner: Custom Foam Inserts

Efficiency in Packaging & Logistics

Speed of Packing

- Custom Foam Inserts: Ready-to-use—just place the product in its slot.

- Bubble Wrap: Requires manual wrapping, taping, and adjustment

Space Optimization

- Custom Foam Inserts: Designed to fit products and boxes precisely, reducing wasted space.

- Bubble Wrap: Adds extra bulk, increasing box size and shipping costs.

Shipping Weight

- While both materials are lightweight, bubble wrap can require more layers, which increases dimensional weight. Custom foam inserts can be optimized to minimize unused volume.

Sustainability & Environmental Impact

Foam inserts can be reused many times without losing integrity, making them ideal for reverse logistics, equipment rentals, or demo kits.Material Recyclability:

- Custom Foam Inserts: Many types, including PE foam, are recyclable.

- Bubble Wrap: Made from LDPE plastic, recyclable in some areas but less accepted.

Waste Reduction:

- Custom Foam Inserts: Reduce excess packaging by eliminating the need for multiple wraps.

- Bubble Wrap: Often overused, leading to higher material waste.

Reusability:

- Foam inserts can be reused many times without losing integrity, making them ideal for reverse logistics, equipment rentals, or demo kits.

Brand Image & Presentation

Today’s unboxing experience can make or break customer impressions.

- Custom Foam Inserts: Deliver a premium look. Products arrive perfectly positioned, enhancing brand professionalism.

- Bubble Wrap: Protects the product but gives a less polished presentation, especially for luxury goods.

Cost Analysis: Short-Term vs Long-Term

Initial Costs

Bubble wrap costs less upfront per package. Foam inserts have a higher one-time setup cost for design and cutting.

Total Cost of Ownership

When factoring in reduced damage rates, faster packing times, and reusability, foam inserts often win on cost savings.

Industry-Specific Recommendations

Custom Foam Parts has supplied packaging solutions for diverse industries, and each has unique needs:

- Electronics: Foam inserts prevent static buildup and protect sensitive circuits.

- Medical Devices: Precise fit ensures compliance with shipping regulations.

- Glassware & Ceramics: Eliminates micro-movement that causes cracks.

- Luxury Goods: Enhances unboxing experience and perceived value.

- Tools & Equipment: Withstands repeated shipping and handling.

Detailed Feature Comparison Table

| Feature | Custom Foam Inserts | Bubble Wrap |

|---|---|---|

| Shock Absorption | Excellent | Good |

| Movement Control | Perfect fit | Limited |

| Reusability | High | Low |

| Brand Presentation | Premium | Average |

| Eco-Friendliness | High (with recyclable foam) | Low to moderate |

| Initial Cost | Higher | Lower |

| Long-Term ROI | Excellent | Average |

Real-World Case Study

A premium wine distributor shipping delicate bottles across the country reduced breakage rates from 8% to 0.5% after switching from bubble wrap to custom foam inserts from Custom Foam Parts. They also reported 30% faster packing and an increase in repeat orders, as customers appreciated the upgraded presentation.

Choosing the Right Foam Type

Custom Foam Parts offers a range of foam materials:

- PE Foam (Polyethylene): Rigid, water-resistant, ideal for heavy-duty shipping.

- PU Foam (Polyurethane): Soft, compressible, great for lightweight cushioning.

- EVA Foam: Dense with a premium feel—perfect for retail packaging.

- Anti-Static Foam: Protects electronics from static discharge.

Faqs

Are custom foam inserts worth the investment for small businesses?

Yes—lower damage rates and faster packing times often offset the initial cost.

Can I brand custom foam inserts?

Industry-Specific Recommendations

Absolutely. Custom Foam Parts can add colors, shapes, and even logos for a professional touch.

Does bubble wrap ever outperform foam?

For irregular, lightweight items that aren’t high-value, bubble wrap can be more cost-effective.

How long do foam inserts last?

With normal handling, quality foam inserts can last for years without losing performance.

Can I mix bubble wrap and foam inserts?

Yes—many companies use foam inserts for core protection and bubble wrap as extra padding for secondary items.

Are there biodegradable foam options?

Yes—some foams are made from plant-based materials that decompose faster than traditional plastics.

Final Verdict

For most businesses shipping fragile, high-value, or precision items, custom foam inserts outperform bubble wrap in protection, efficiency, brand presentation, and sustainability. While bubble wrap has its place for lightweight, irregular, or temporary shipments, it can’t match the tailored performance of foam inserts.

If you’re ready to reduce damage rates, improve unboxing experiences, and streamline packing, Custom Foam Parts offers fully customized solutions that give you an edge over competitors.