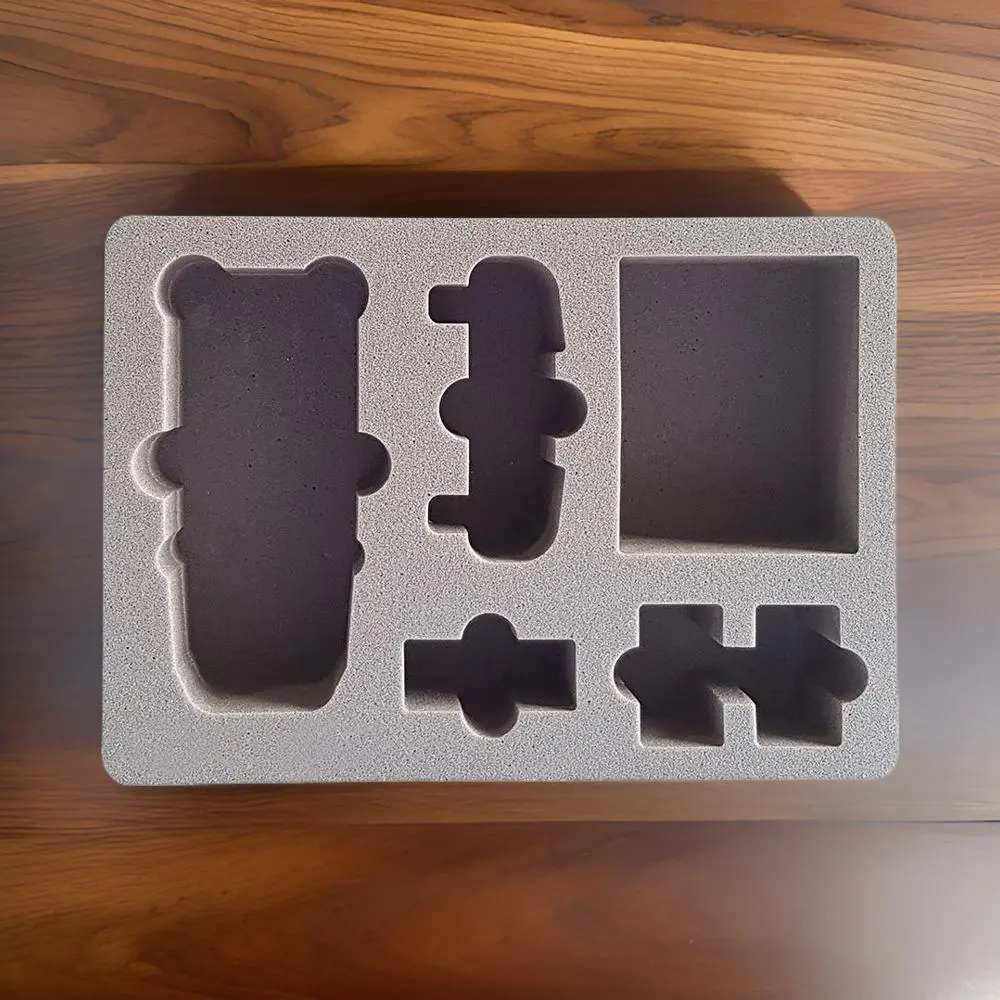

Custom Foam Inserts help keep your electronics safe, neat, and looking good. These inserts are carefully designed to fit devices of all shapes and sizes, keeping them safe from bumps, shakes, and rough handling. Whether you’re sending or storing circuit boards, cameras, tablets, or drones, Custom Foam Parts keeps them safe and makes sure they arrive looking neat

Why Are Custom Foam Inserts Essential for Electronics?

Shipping and handling electronics come with high risk. Sensitive components like motherboards, sensors, and screens are vulnerable to even minor impacts. That’s where custom foam inserts step in. Unlike generic packaging, these inserts are tailored to the exact shape and size of your device, offering a snug fit and layered protection.

Key Benefits:

- Shock Absorption: Minimizes impact from drops or rough transport.

- Scratch Prevention: Prevents surface damage, particularly for glossy screens and delicate casings.

- Electrostatic Safety: Options like anti-static foam prevent electrostatic discharge (ESD), which can destroy electronic circuits.

- Professional Appearance: Offers clean and organized packaging for product presentations or retail.

- Cost Savings: Reduces returns and warranty claims due to shipping damage.

Materials Used in Custom Foam Inserts

Different electronics require different levels of protection. That’s why Custom Foam Parts provides a variety of foam materials tailored for specific electronic packaging needs:

Polyethylene (PE) Foam

- Closed-cell structure: The closed-cell structure of this foam makes it highly resistant to water, oils, and chemicals, providing excellent protection against moisture and contamination. It’s perfect for environments that require hygienic and durable materials.

- Excellent shock absorption:This foam offers superior shock absorption capabilities, making it ideal for safeguarding delicate or sensitive items during transit or storage. It effectively disperses impact energy to reduce the risk of damage from drops or vibrations.

- Ideal for repeated use:Thanks to its durability and shape-retaining properties, this foam is perfect for repeated handling and long-term usage. It won’t easily compress or degrade, maintaining consistent protection even after frequent use or multiple packaging cycles.

- Commonly used:Widely used in a range of industries including electronics, aerospace, medical devices, and retail packaging, this foam is trusted for its versatility. It’s often found in custom cases, product displays, tool organizers, and protective inserts.

Polyurethane (PU) Foam

- Open-cell structure:The open-cell structure allows air and moisture to pass through, making it lightweight and breathable. Ideal for applications where airflow, softness, or sound absorption is beneficial and necessary.

- Softer and more flexible:This foam type offers a plush, cushion-like feel and adapts easily to irregular shapes. Its flexibility makes it suitable for wrapping, lining, or protecting fragile items with complex contours or surfaces.

- Perfect for delicate items:Commonly used for electronics, glassware, or sensitive instruments, this foam gently cradles items to prevent scratches, cracks, or pressure damage during transport or storage in dynamic environments.

EVA Foam

- Offers a blend of durability and softness: This foam strikes the perfect balance between firm support and gentle cushioning, making it ideal for protecting items that need both shock resistance and a soft touch during handling or shipping.

- Highly customizable and colorful:Available in a wide range of densities, colors, and finishes, this foam can be tailored to match your brand identity or functional needs, including custom shapes, layered designs, and visual appeal enhancements.

- Often used for consumer electronics and retail packaging:Its clean appearance, lightweight feel, and protective properties make it a go-to choice for packaging phones, tablets, accessories, and small gadgets where presentation and protection are both key.

Anti-Static Foam

- Protects sensitive components from electrostatic discharge:This foam features anti-static or conductive properties that help dissipate static electricity, preventing damage to delicate electronics during packaging, transport, or assembly handling.

- Ideal for circuit boards, processors, and memory devices:Its specialized formulation makes it safe for direct contact with components that are highly susceptible to static shock, ensuring long-term reliability and preventing costly equipment failures.

Each foam type can be cut and layered to meet the specific dimensions and protection requirements of your product.

Customization Options Available at Custom Foam Parts

At Custom Foam Parts, we take customization seriously. Here’s what you can tailor:

Precision Cutouts

CNC-machined or die-cut to match the exact shape of your product. These cutouts ensure a snug fit, minimize movement during transit, and enhance presentation by keeping everything neatly in place.

Multi-Layer Inserts

Stacked layers provide additional cushioning for larger or multi-piece equipment. This design allows for tiered organization, easy access, and added protection for sensitive components at different levels.

Color Options

Differentiate your brand or organize by color for ease of identification. Choose from a wide range of vibrant or subtle foam colors to enhance visual appeal or simplify sorting for teams or customers.

Branding & Logos

Add your logo or part labels directly onto the foam insert for a premium look. Laser etching, embossing, or colored printing helps reinforce brand identity and creates a professional, custom finish.

Mixed Material Kits

Combine foam inserts with hard cases, plastic trays, or cardboard for versatile packaging solutions. This hybrid approach offers the best of both protection and presentation for various product types.

Industries That Benefit from Custom Foam Inserts

While electronics are a major use case, many industries benefit from custom foam inserts:

| Industry | Application Example |

|---|---|

| Consumer Electronics | Smartphones, tablets, VR headsets |

| Medical Devices | Diagnostic tools, portable monitors |

| Aerospace | Avionics systems, sensors |

| Automotive | ECU units, infotainment systems |

| Industrial Equipment | Control panels, testing gear |

| Photography | Drones, cameras, lenses |

Use Cases: Custom Foam Inserts in Real Applications

Let’s look at how businesses leverage Custom Foam Parts to protect their electronics:

Case Study 1: Drone Packaging for E-commerce

An e-commerce retailer used our PE foam inserts to protect drones during global shipping. The custom layout included cavities for the drone, controller, propellers, and charger, ensuring no component shifted in transit.

Case Study 2: Anti-Static Foam for Circuit Boards

A tech manufacturer required anti-static custom foam inserts for sensitive circuit boards. Our solution reduced electrostatic risks and minimized damage rates by over 40% within three months.

The Process: From Concept to Delivery

Creating custom foam inserts for electronics is a seamless process with Custom Foam Parts:

Step 1: Product Assessment

You share details or send a CAD file/product dimensions. Our team carefully evaluates the item’s shape, surface sensitivity, and packaging goals to determine the best custom fit and protection strategy.

Step 2: Material Selection

Based on the item’s fragility and weight, we recommend the best foam type. Whether you need closed-cell foam for waterproofing or soft PU for delicate items, we ensure optimal balance of durability and protection.Step 3: Design & Prototyping

Our design team creates a 3D layout for approval. We simulate real-world use, evaluate compartment sizing, and adjust for labeling, branding, or multi-level storage to meet functional and aesthetic needs.

Step 4: Cutting & Fabrication

Using precision cutting tools (CNC, water jet), your inserts are crafted to spec. We maintain tight tolerances, clean edges, and smooth contours to ensure the final insert fits your product like a glove.

Step 5: Quality Control & Delivery

Each batch goes through rigorous QC before being delivered on time. We inspect for dimensional accuracy, material integrity, and finish quality, ensuring your custom inserts meet every performance benchmark.Each batch goes through rigorous QC before being delivered on time. We inspect for dimensional accuracy, material integrity, and finish quality, ensuring your custom inserts meet every performance benchmark.

Environmental Considerations Considerations

While synthetic foams are used widely, Custom Foam Parts also offers:

These foams are designed to be recycled after use, reducing landfill waste and supporting a circular economy. They offer reliable protection while aligning with eco-friendly packaging goals.

Made from plant-based or compostable materials, these biodegradable foams naturally break down over time. They provide a sustainable option without compromising cushioning or protection.

Engineered for multiple uses, these packaging designs help reduce single-use waste. They’re durable, easy to clean, and ideal for returnable shipments or long-term storage solutions.

We aim to balance durability and environmental responsibility in every packaging solution.

Comparison: Custom Foam Inserts vs. Standard Packaging

| Feature | Standard Packaging | Custom Foam Inserts |

|---|---|---|

| Fit | One-size-fits-most | Precision-cut to product |

| Shock Protection | Minimal | Excellent |

| Brand Appearance | Basic | Premium look |

| Return Damage Rates | High | Very low |

| Cost Efficiency (long run) | Low | High |

Custom foam inserts not only elevate your packaging but also protect your bottom line.

Why Choose Custom Foam Parts?

We’re not just another packaging company. Custom Foam Parts is your partner in providing intelligent, safe, and reliable foam solutions for electronics.

What Sets Us Apart:

- Fast Turnaround Times

- CAD Design Support

- ISO-Certified Manufacturing

- Volume Flexibility (Low & High Orders)

- USA-Based Support & Shipping

We’ve worked with businesses across healthcare, aerospace, tech, and logistics to deliver foam solutions that perform in real-world environments.

Conclusion

Custom foam inserts are no longer a luxury—they’re a necessity in the world of electronics. Whether you’re shipping smartphones, securing circuit boards, or storing drones, the right foam insert can mean the difference between a damaged product and a flawless delivery. At Custom Foam Parts, we specialize in crafting foam solutions that protect, impress, and deliver results.

Faqs

What are custom foam inserts used for?

Custom foam inserts are used to protect items during shipping or storage by securely holding them in place and absorbing shocks or impacts.

Can foam inserts be made anti-static?

Yes, anti-static foam inserts are ideal for packaging sensitive electronic components that could be damaged by static electricity.

Are custom foam inserts reusable?

Absolutely, many foam inserts, especially those made from PE and EVA foam, are durable enough for repeated use, making them ideal for returnable packaging or equipment cases .

What information do I need to provide for custom inserts?

To create a precise insert, you’ll need to provide dimensions, weights, and preferably 3D CAD files or physical samples of the electronics to be packaged.

How long does it take to get custom foam inserts?

At Custom Foam Parts, the lead time can vary depending on order size and complexity, but we typically deliver within 7–14 business days.