When customers receive a damaged product, it creates frustration, disappointment, and complaints. For the business, that often leads to extra work, bad reviews, and lost trust. One of the simplest ways to solve this problem is by using custom foam inserts. These inserts are designed to match your product’s exact shape, protecting it from every angle. By holding the product firmly in place, foam inserts prevent movement, absorb shocks, and eliminate common causes of shipping damage. That’s how custom foam packaging helps reduce returns and improve customer satisfaction every single time.

What Are Custom Foam Inserts and Why Do They Matter?

Custom foam inserts are specially shaped foam pieces that sit inside product packaging. Instead of using loose filler like shredded paper or air pillows, these inserts are cut to fit the product perfectly. They keep it snug, stable, and protected. This is called foam insert protection, and it’s one of the smartest ways to ship anything valuable, fragile, or irregularly shaped.

Common materials used in custom foam solutions include PE (polyethylene), PU (polyurethane), and EVA foam. PE is firm and resistant to compression. PU is soft and flexible, ideal for delicate items. EVA sits in between—it’s smooth, long-lasting, and offers a clean appearance.

These foams are shaped using machines like CNC routers and die cutters. The final result is a packaging insert that holds the item in place like a glove. The tighter the fit, the lower the chance of movement and the lower the chance of damage during shipping.

Real Impact of Foam Insert Protection: Before and After

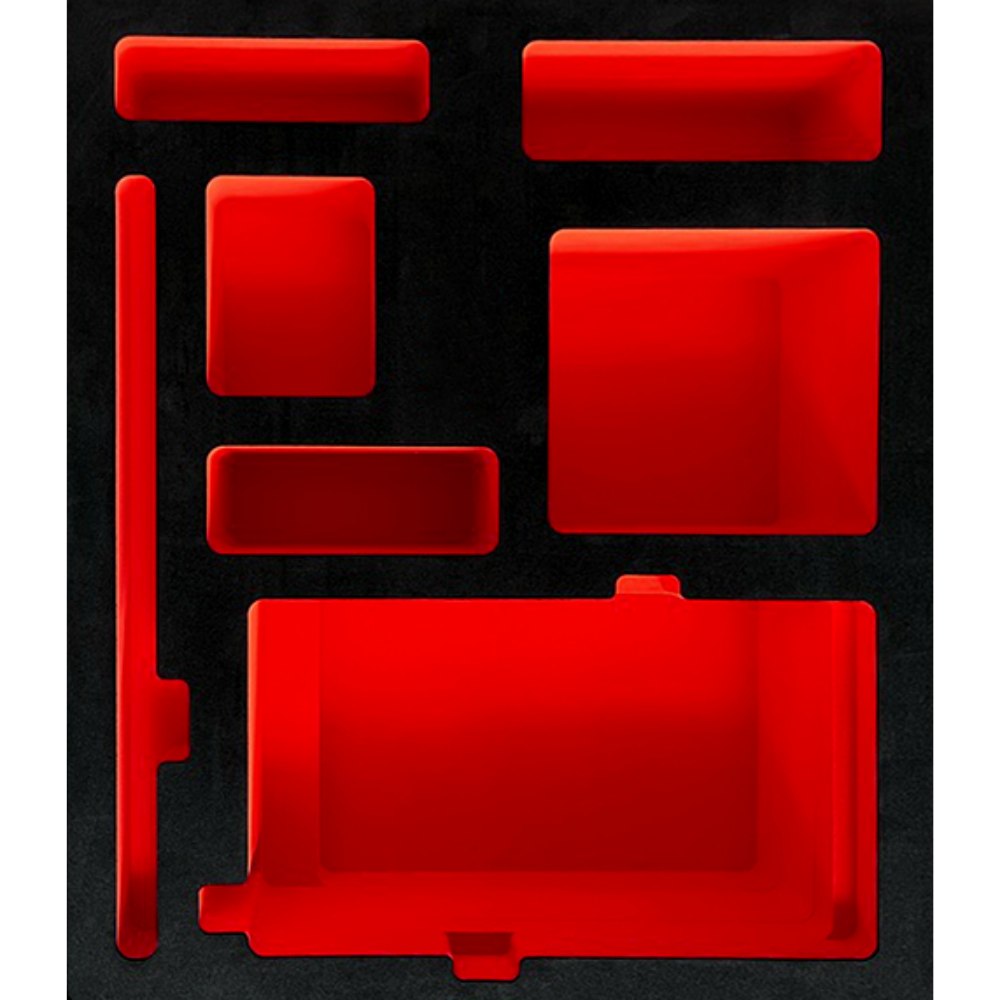

Below is a simple visual comparison between packages shipped with and without custom foam inserts.

| Feature | Without Foam Insert | With Custom Foam Insert |

|---|---|---|

| Shipping Condition | High | None |

| Product Movement Inside Box | High | None |

| Surface Damage | Frequent | None |

| Broken or Cracked Items | Often | Rare |

| Customer Complaints | Regular | Minimal |

| Brand Presentation | Poor | Professional and Clean |

| Unboxing Experience | Messy, Cheap | Neat, Premium |

The difference is clear. With custom foam packaging, you’re not just protecting the product you’re also creating a better first impression. Your packaging speaks before your product does.

Foam Inserts in Action: Why They Actually Work

Packages travel a rough path. They’re tossed in trucks, dropped on docks, and squeezed into tight spaces. Boxes might fall, twist, or slam into others. All this movement increases the risk of scratches, cracks, and internal damage. But when a product sits inside a perfectly molded foam pocket, none of that matters.

Custom foam inserts absorb the shock of drops and hits. The foam material slows down impact and spreads it across a wider area, so no one part of your item takes the full hit. Foam also prevents items from shifting or rubbing against the sides of the box.

Another benefit is clean separation. If you’re shipping a product with accessories like a tool with bits, or a bottle with pumps the insert can be designed to give each piece its own spot. That means nothing knocks into anything else. It arrives just the way you packed it.

From fragile glassware to high-end electronics foam insert protection turns everyday shipping into something far more secure. And customers notice. Many say they “feel the care” just by opening a box packed with foam.

Where Custom Foam Inserts Really Shine: Industry Examples

Foam inserts don’t just work, they work in a wide variety of industries. From tech gadgets to cosmetics, brands across the board are using custom foam packaging to reduce complaints and keep their customers coming back. Here are a few real-world product types that benefit most:

In electronics, items like phones, speakers, cameras, and drones require strong protection. Foam holds these items tight and avoids damage to circuits, screens, or lenses. Without it, a simple drop can ruin the product.

In the medical field, foam inserts ensure that surgical tools, test kits, and medical devices arrive sterile and organized. Any shift in transit could make a tool unusable or unclean. That’s why many medical suppliers rely on precision-cut foam.

Cosmetic brands ship products made of glass, plastic, or aluminum. Foam inserts stop items from tipping over, leaking, or breaking. They also give the unboxing a high-end feel, which customers love. It’s not just safer it looks more professional too.

Tool manufacturers use foam insert protection to keep drills, bits, or hand tools locked in place. Not only does it stop damage, but it keeps everything organized and ready to use.

E-commerce brands benefit most. They ship daily, and product damage quickly becomes a problem. Foam inserts lower returns, reduce customer complaints, and improve online reviews. That’s important when your store lives on customer trust.

Why Presentation Matters More Than Ever

Think of the last time you opened a box and everything was just thrown in. Now imagine opening a package where every piece is neatly placed, held in foam, and looking like it belongs there. That’s the difference custom foam makes.

Customers are more likely to post positive reviews, share their unboxing online, and reorder when their product feels like it was packed with care. That extra layer of neatness and security doesn’t just stop damage it builds trust.

This is especially true for premium brands. Whether it’s luxury cosmetics or high-end tech, the Packaging often shapes the customer’s opinion before they even see the product.

Custom Foam Inserts turn your packaging into part of the experience not just something to throw away.

How to Choose the Right Custom Foam Solution for Your Product

Choosing the right custom foam packaging starts with understanding what your product needs. A small item that breaks easily will need a soft, flexible foam that cushions gently. A large, heavy item needs firm foam that won’t compress or shift during shipping.

It also depends on how your product is shaped. Foam can be cut to fit curves, corners, handles, or any unique feature. Some inserts even come with removable layers so the customer can reuse or reconfigure the foam if needed.

Your branding can also influence your choice. Do you want black foam for a luxury look? White for a clean feel? Colored foam to match your brand? All of this is possible with today’s custom foam solutions.

Companies like Custom Foam Parts help you design the right fit. From materials to layout, they walk you through the options and help you decide what works best based on the product, the shipping method, and the customer experience you want to create.

Customer Reviews: Real Feedback on Foam Inserts

These reviews are based on realistic product scenarios from industries that use custom foam:

“Before using foam inserts, we had at least two broken orders a week. Since switching, we haven’t had a single one in over three months. Our customer reviews improved too!”

Sarah M

“We ship glass bottles daily. Foam inserts changed the game. Everything stays upright, no more leaks, and the packaging looks so professional.”

Lisa K

“Our camera gear used to get scratched during shipping. Now everything is separated, protected, and looks amazing in the box. It gives us a real edge.”

Dan R

“The foam solution from Custom Foam Parts was spot on. Everything fits perfect. Zero movement. Customers often mention how clean the packaging is.”

Tom H

“As a small online store, we needed our packaging to stand out and reduce returns. Custom foam gave us both. It makes every order look like a premium gift.”

Priya B

These reviews show how much of a difference proper foam inserts can make—not just for safety, but for branding and customer happiness.

Final Thoughts

Shipping should never feel like a gamble. Whether you’re mailing a delicate perfume bottle, a drone, or a beauty set, you want it to arrive safely, looking just as good as when it left your hands. Custom foam inserts give your products the support they need to survive bumps, drops, and rough handling.

Beyond protection, foam inserts also help improve customer trust. They make your packaging look cleaner, more professional, and more cared for. When customers open a box and everything is neatly tucked in place, they feel confident about your brand.

With support from packaging experts like Custom Foam Parts, you can find the perfect foam fit for any product simple or complex. So if reducing returns and complaints matters to your business, foam inserts aren’t just helpful they’re essential.

FAQs

What are custom foam inserts made of?

They’re typically made from PE (polyethylene), PU (polyurethane), or EVA foam. Each has different strengths depending on your product’s weight and fragility.

Can custom foam inserts be used for any product shape?

Yes, foam can be cut to match nearly any shape—rounded, flat, detailed, or complex. That’s what makes it such a good fit for fragile and unique items.

Is foam packaging good for branding?

Absolutely, it adds a clean, professional appearance and gives customers a strong first impression when they open the package.

Can I get foam inserts in different colors?

Yes, many providers offer black, white, or even custom-colored foam to match your brand or create a unique unboxing experience.

Are custom foam inserts reusable?

Yes, depending on the material, many foam inserts can be reused several times, especially in toolkits or product cases.