To choose the right custom ESD foam inserts, assess your electronics’ sensitivity, select the correct ESD foam type, and ensure the fit protects against static damage.

What Are Custom ESD Foam Inserts?

Custom ESD foam inserts are specially engineered foam solutions designed to protectelectronic components from electrostatic discharge (ESD). These foams are customized to fit your products and packaging needs, providing both physical cushioning and static protection.

Used in industries like electronics manufacturing, aerospace, defense, and medical equipment packaging, these inserts prevent static buildup that could damage sensitive devices like circuit boards, processors, and integrated chips.

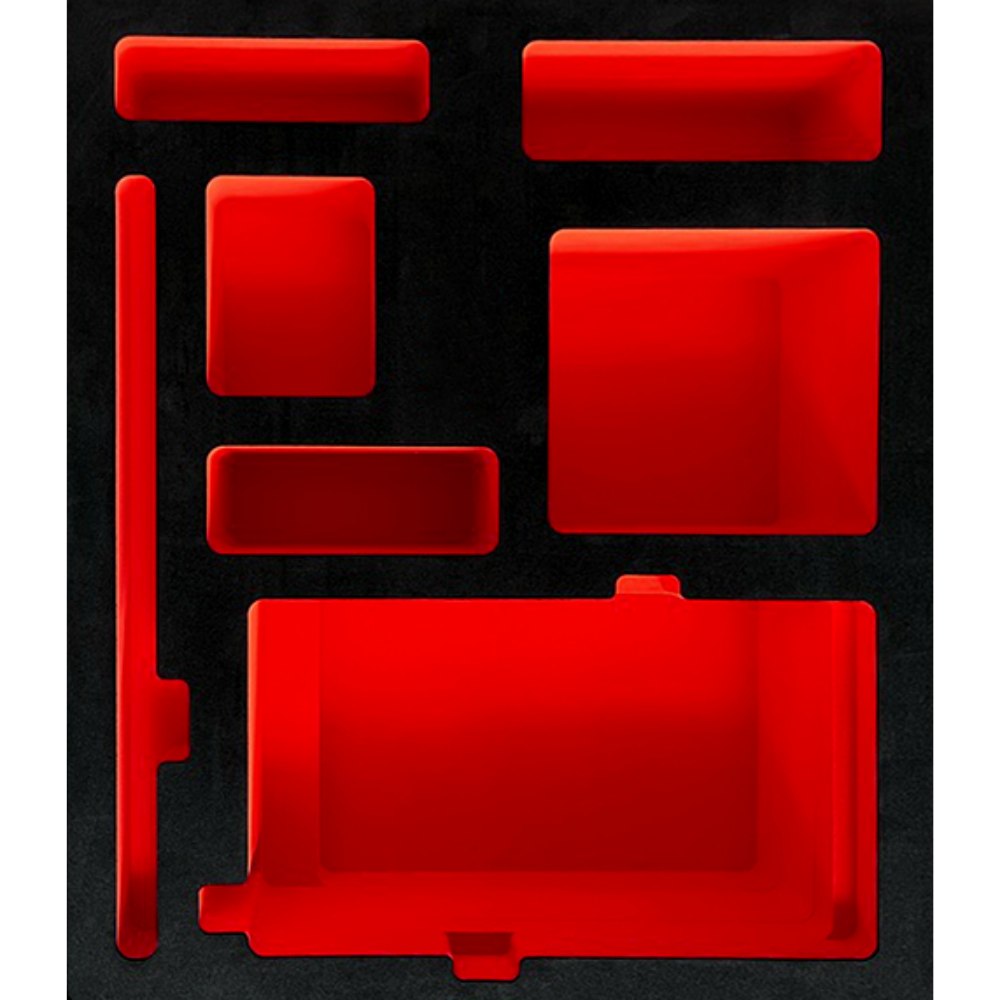

The customization factor allows for foam inserts that match your product’s dimensions, shape, and sensitivity requirements. Whether you need them in trays, boxes, or case inserts, these foams can be tailored precisely to reduce handling damage and improve logistical efficiency.

Why ESD Protection Matters in Electronics Packaging

Static electricity might seem harmless, but in electronics packaging, it’s a major threat. Electrostatic discharge can fry microchips, damage circuitry, and cause latent defects that result in product failure after delivery.

Every time components are handled or transported without proper ESD protection, there’s a risk. This is especially true for printed circuit boards (PCBs), processors, and memory modules.

Investing in custom ESD foam inserts significantly reduces the chances of:

- Product malfunction

- Costly returns or recalls

- Brand reputation damage

- Customer dissatisfaction

- Supply chain delays due to replacement needs

Compliance with standards such as ANSI/ESD S20.20 and IEC 61340 ensures your business meets industry benchmarks for electrostatic protection. In highly regulated sectors such as aerospace, medical devices, and military applications, such compliance is not optional—it’s essential.

Types of ESD Foam Inserts

Understanding the types of ESD foam helps you choose the right one for your product:

Conductive Foam

- Surface Resistivity: 103 to 105 Ohms/sq

- Use Case: High-sensitivity devices like microprocessors and memory chips

- Features: Fast static discharge, often black in color

- Benefits: Offers a path for electricity to travel away from the component

Dissipative Foam

- Surface Resistivity: 10^6 to 10^9 Ohms/sq

- Use Case: PCBs, telecom equipment

- Features: Slower discharge, controlled flow of current

- Benefits: Reduces the risk of damaging sudden discharges

Anti-Static Foam

- Surface Resistivity: 109 to 1012 Ohms/sq

- Use Case: Handling trays and storage

- Features: Prevents charge buildup, usually pink or blue

- Benefits: Minimizes generation of static during handling

Each foam type is available in materials like polyethylene (PE), polyurethane (PU), and cross-linked PE, allowing for tailored properties such as durability, softness, and density. These materials can be shaped, layered, or combined to suit different levels of protection and environmental resistance.

Key Factors to Consider When Choosing ESD Foam Inserts

Material Type

Choose the foam based on your need:

- PE foam: Durable and rigid, excellent for heavier items

- PU foam: Softer, flexible cushioning, ideal for lighter and delicate components

- XLPE: Closed-cell structure, water-resistant, and more durable

Surface Resistivity Ratings

Match the resistivity to your device’s ESD tolerance:

- Conductive: 10³–10⁵ Ohms

- Dissipative: 10⁶–10⁹ Ohms

- Anti-static: 10⁹–10¹² Ohms

Foam Density and Thickness

Heavier products need denser and thicker foam. Lightweight items may benefit from soft, low-density foam. Consider multilayer foam solutions to optimize weight, durability, and ESD performance.

Product Shape and Weight

Custom cutting ensures precise fit. Irregular shapes may require CNC routing or die-cutting. Products with sharp edges may benefit from foam layering to avoid punctures and provide better shock absorption.

Component Sensitivity

More sensitive electronics require higher-grade ESD protection. For example, high-frequency components, semiconductors, and optical devices are more vulnerable to even minimal discharges.

Environmental Factors

Account for storage or shipping conditions:

- Humidity

- Vibration

- Temperature fluctuations

- Altitude changes

For instance, XLPE performs better in fluctuating temperature environments than standard PU foam.

Reusability

Reusable foam inserts save money in long-term logistics. Single-use foams are better for sterile or one-time shipments. Determine your lifecycle needs and choose accordingly.

The Role of Customization in Foam Insert Design

Customization ensures that your packaging meets both protection and presentation needs. At Custom Foam Parts, we use:

- CAD-based Design: Accurate modeling of foam cavities

- CNC Routing: For intricate and precise cuts

- Laser Etching: For part numbers or branding

- Prototyping: So you can test before full-scale production

Benefits:

- Enhanced shock absorption

- Reduced product movement

- Improved brand presentation and compliance

- Better warehouse organization and part identification

Customized foam packaging also reduces packaging waste and optimizes the use of shipping space. This can lead to savings on freight and packaging material costs.

Applications of Custom ESD Foam Inserts

Our ESD foam inserts serve multiple industries:

- Electronics Manufacturing: PCBs, processors, chips

- Aerospace and Defense: Navigation systems, sensors, avionics

- Medical Equipment: Scanners, handheld diagnostic devices, surgical instruments

- Telecommunications: Routers, satellite components, signal processors

Example:

A manufacturer of sensitive RF components reduced product failure by 92% after switching to our custom ESD foam solutions. This resulted in a 23% decrease in return-related costs and improved customer satisfaction.

How to Work with a Foam Design Specialist

At Custom Foam Parts, we simplify the design-to-delivery process:

Initial Consultation

Share your product specs, size, and ESD sensitivity levelPrototype Design

We build a sample based on CAD modeling

Testing and Validation

Check fit and ESD performance

Full Production

Once approved, we begin bulk manufacturingAdjust designs as your product evolves

Ongoing Support

Adjust designs as your product evolvesPartnering with us ensures consistency, speed, and quality in your packaging supply chain. You gain access to design engineers, tooling experts, and fast-turnaround production.

Cost Considerations and ROI

While custom ESD foam inserts may cost more upfront, they reduce losses from damaged goods and ensure compliance.

Cost Factors:

- Foam material type

- Complexity of custom cuts

- Volume of order

- Required certifications

- Packaging design (layers, adhesives, trays)

ROI Benefits:

- Fewer returns

- Safer shipping

- Long-term reusability

- Reduced insurance costs

- Higher perceived product value

Startups can begin with small batch orders, then scale up. Our flexible MOQs allow businesses of all sizes to benefit from tailored ESD protection.

Compliance and Sustainability Factors

We offer ESD foam inserts that meet:

- RoHS Compliance: No restricted hazardous substances

- REACH Standards: Safe for human health and environment

- ISO 9001 Certified Production

- ANSI/ESD S541 Packaging Material Compliance

We also provide:

- Recyclable foam materials

- Biodegradable options on request

- FSC-certified packaging for ESG compliance

- Bulk packaging designs to reduce shipping waste

Choosing sustainable foam not only meets compliance but also boosts your brand’s green credentials

Common Mistakes to Avoid

We are your go-to source for custom foam parts in New Hampshire because:

Standard foam builds up static

Wrong rating can cause damage

Poorly cut inserts allow movement and shocks

Fit and performance issues go unnoticed

Lack of compliance certificates

Incorrect handling can defeat ESD protection

Avoiding these mistakes ensures long-term success and product reliability.

Future Trends in ESD Foam Insert Technology

- Smart Packaging: Integration with RFID/NFC

- Eco-Friendly Materials: Focus on sustainability and recycling

- 3D Printed Tooling: Faster prototyping and customization

- AI-Driven Foam Design: Optimize cuts and material usage with machine learning

- Hybrid Foam Materials: Combining ESD and thermal insulation properties

- IoT Integration: Tracking inserts and assets in real-time

Make the Right Choice for Protection

Choosing the right custom ESD foam inserts is essential for protecting sensitive electronics. By understanding your product’s requirements, selecting the correct foam type, and working with experts like Custom Foam Parts, you ensure safe delivery, compliance, and reduced returns.

Let us help you design a custom foam solution that aligns with your technical needs, sustainability goals, and budget.

Faqs

What is the best ESD foam type for microchips?

Conductive foam offers the best protection for microchips due to its fast static discharge.

How can I test if foam is ESD-safe?

Use an ESD surface resistivity meter to verify that it falls within the required Ohms range.

Can I reuse ESD foam inserts?

Yes, if the foam maintains its structure and ESD properties. Choose durable materials like XLPE.

What certifications should I look for?

RoHS, REACH, and ESD compliance certifications are key.

What industries rely most on ESD foam inserts?

Electronics, aerospace, defense, telecom, and medical sectors.

Can custom ESD foam inserts be color-coded?

Yes, to aid with inventory sorting, product identification, and branding.

Are there foam inserts suitable for cleanroom environments?

Yes, certain foams are manufactured in ISO cleanroom conditions and meet medical or semiconductor standards.