As smart home technology becomes an essential part of modern living, protecting these high-value, fragile electronics during shipping is more important than ever. Devices like smart thermostats, video doorbells, Wi-Fi cameras, smart locks, and voice assistants contain delicate sensors and electronic components that can easily be damaged in transit.

Custom foam inserts offer an ideal solution to ensure these devices reach customers safely, preserving brand reputation and reducing costly returns. In this guide, we will explore how custom foam inserts protect smart home devices in transit, why they are superior to generic packaging, and how Custom Foam Parts leads the industry in creating precision protective packaging.

What Are Custom Foam Inserts?

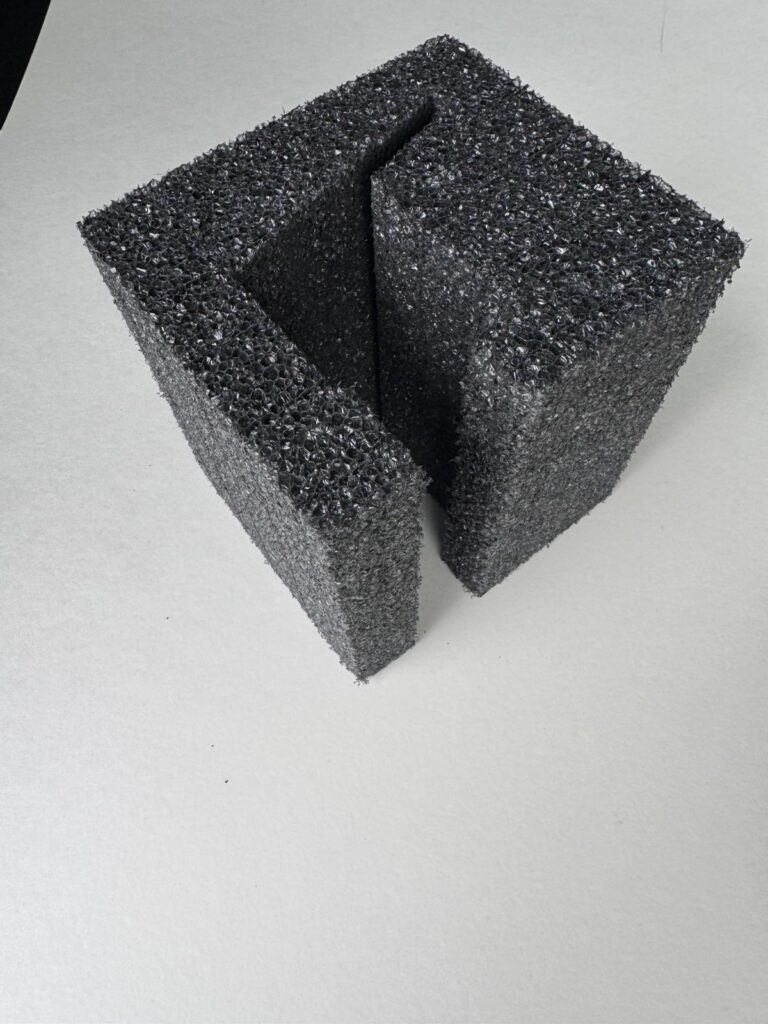

Custom foam inserts are specially designed protective components that cradle a product within its packaging. Unlike off-the-shelf solutions, these inserts are tailored to the exact shape and specifications of the product they protect. This level of customization offers a snug fit that prevents movement and absorbs shock, two of the main causes of transit-related damage.

At Custom Foam Parts, we use state-of-the-art CAD modeling, CNC cutting, and a variety of foam materials to develop packaging solutions that meet both functional and aesthetic needs. Our inserts are designed to fit seamlessly into retail boxes or shipping containers, combining durability with brand presentation.

How Custom Foam Inserts Ensure Transit Safety for Smart Home Devices

Smart home devices are often shipped across states, countries, or even continents. During this journey, they may face vibrations, drops, temperature changes, and pressure. The combination of fragile screens, circuit boards, and glass components makes smart devices highly susceptible to damage.

Impact Absorption

Custom foam inserts are engineered to absorb impact. Whether the package is dropped or jostled during shipping, the foam absorbs the shock and prevents the device from sustaining damage. This is especially critical for items like smart thermostats or smart displays that feature glass screens and internal sensors.

Vibration Dampening

Transport vehicles generate constant micro-vibrations. Over time, these vibrations can affect the integrity of the device’s components. Foam inserts for fragile items act as a cushion, isolating the device from vibrations and keeping internal components stable.

Secure Positioning

Loose packaging leads to product movement within the box. Custom foam inserts hold the smart device in a fixed position, ensuring it remains immobile throughout transit. This level of precision dramatically reduces risk during accidental mishandling.

Protection Against Environmental Factors

Depending on the foam type, inserts can also provide insulation against temperature extremes or moisture ingress. This is important for devices sensitive to heat, cold, or humidity, such as smart sensors or battery-powered devices.

Smart Device Shipping Protection: Why Generic Packaging Falls Short

While bubble wrap and standard cardboard inserts may provide some degree of cushioning, they lack the tailored fit necessary for true protection. Smart device shipping protection demands a solution designed specifically for the item being shipped.

Generic packaging materials like loose fill or bubble wrap fail to secure items in place. This allows smart devices to shift inside the box, increasing the risk of internal damage during transit or storage.

Without custom contours or tailored cushioning, standard packaging fails to evenly absorb shock. This creates pressure points that may crack screens or dislodge internal components during handling.

Off-the-shelf packaging is often made from lower-quality materials that flatten, tear, or lose elasticity. This reduces long-term protection, especially for products stored or shipped multiple times.

Generic inserts don’t support a premium unboxing experience. They lack cohesive design, color matching, and brand elements that enhance perceived value and trust in smart device packaging.

Custom foam inserts, on the other hand, offer a professional look and dependable protection from production to delivery.

Protective Packaging for Electronics: Foam Insert Material Options

At Custom Foam Parts, we offer a wide selection of foam types to suit various protective packaging needs for electronics, including:

Polyethylene (PE) Foam

PE foam is a high-density material ideal for rugged applications. It offers strong shock absorption, water resistance, and reusability. It’s great for stacking smart devices without damaging their structure.

Polyurethane (PU) Foam

PU foam is softer and more flexible, perfect for products with delicate surfaces. It conforms to the shape of the product and prevents abrasions. It’s ideal for smart displays, lenses, and glass-covered gadgets.

EVA Foam

EVA foam combines durability with visual appeal. Its smooth finish is excellent for showcasing premium products while ensuring strong impact protection. It’s widely used in retail-ready electronics packaging.

Each material can be cut, laminated, or even laser-engraved to include logos, part numbers, or color-coded indicators for easy identification.

Custom Packaging Solutions for Smart Home Brands

Packaging is more than just protection. It plays a key role in unboxing experiences, branding, and customer satisfaction. Custom Foam Parts works with smart device manufacturers, e-commerce brands, and logistics providers to deliver complete custom packaging solutions that protect and impress.

Branding Meets Functionality

Foam inserts can be color matched to your brand or include custom cut-outs for cables, instruction manuals, and accessories. This makes the packaging intuitive for the end user and enhances perceived product value.

Scalable Production

Whether you’re a startup shipping a few hundred units or a global brand with monthly rollouts, Custom Foam Parts offers scalable solutions. Our fast turnaround and low minimum order quantities make us the go-to partner for businesses of all sizes.

Real-World Example: Protecting a Smart Doorbell in Transit

Imagine a smart doorbell with a touchscreen, motion sensor, camera, and rechargeable battery. During shipping, this device may encounter:

Impacts during loading and unloading

Packages are frequently dropped or tossed during manual loading and unloading at warehouses or trucks. A custom foam insert helps absorb these shocks, preventing external cracks and internal component failure.

Vibration during ground or air transport

Long-distance transportation exposes packages to constant vibrations from road bumps or air turbulence. These small but repeated vibrations can loosen components, which foam inserts help minimize effectively.

Stacking pressure in warehouses

In storage, packages are often stacked one over another. This weight causes pressure that may deform or damage fragile smart devices. Foam inserts distribute this pressure evenly, avoiding stress points or crushing.

Temperature changes across regions

Shipments pass through varied climates, from hot storage areas to cold delivery vans. These shifts can affect batteries and sensors. Temperature-resistant foam adds insulation, helping maintain internal stability.

Using a custom foam insert, the doorbell is secured in a precision-molded compartment with separate slots for mounting hardware and charger. The foam prevents movement, absorbs shock, and enhances the unboxing experience. With these benefits, the chances of a return or negative review due to damage are significantly reduced.

Foam Inserts for Fragile Items: Beyond Just Electronics

While smart home devices are a major use case, custom foam inserts are also perfect for:

Drones and UAVs

Custom foam inserts provide essential protection for delicate drone parts such as propellers, cameras, and batteries. They prevent movement during transit and protect against shock, dust, and vibration.

VR and AR Headsets

These headsets are often made with lenses, sensors, and head straps that can be easily damaged. Custom foam inserts hold them securely, minimizing risk and enhancing presentation for premium user experience.

Home Audio Equipment

Speakers, amplifiers, and smart soundbars have sensitive components that can break or shift. Foam inserts ensure that every piece stays in place, protecting wires, casings, and control knobs from impact.

Medical Sensors

Medical electronics demand high levels of protection and cleanliness. Foam inserts cradle each sensor safely while also reducing contamination risk during storage and shipping across various environments.

Photography Gear

Lenses, cameras, and accessories are expensive and fragile. Foam inserts with custom-cut cavities hold each piece tightly, preventing movement and damage while also offering a professional display on arrival.

If it’s fragile, compact, and valuable, it needs a custom-fit solution to ensure safe delivery.

Why Choose Custom Foam Parts?

Custom Foam Parts has earned a reputation for delivering excellence in protective foam packaging. Here’s what sets us apart:

In-house CAD Design

Our expert engineers use 3D modeling to tailor each foam insert to your device. This results in a flawless fit that maximizes protection and minimizes material waste, making the packaging more efficient and cost-effective.Advanced Machinery

Using CNC routers, die-cutting tools, and laser engravers, we create foam inserts with precise dimensions and smooth edges. This ensures professional presentation and repeatable results at any scale.

Material Expertise

Our team helps select foam based on your product’s weight, fragility, and environmental needs. We test different materials to find the best combination of durability, softness, and visual appeal for your product.

Quick Turnaround

We understand how critical launch dates and restocks are. Our streamlined process delivers your foam inserts quickly, without compromising quality. You can rely on us to meet demanding shipping deadlines.

Low MOQ

We support small and medium businesses by offering low minimum order quantities. Whether you’re launching a new product or testing the market, we make professional-grade packaging accessible and affordable.Our goal is to give your product the protective packaging it deserves—every time.

Conclusion

Shipping fragile, high-tech smart home devices requires more than standard packaging. Custom foam inserts provide superior protection, enhanced brand presentation, and peace of mind for both sellers and buyers.

By choosing Custom Foam Parts, you are investing in a packaging solution that reduces damage, lowers returns, and improves customer satisfaction. Our team is ready to help you create foam inserts that reflect the quality of your products and the professionalism of your brand.

Want to Get Started?

Contact Custom Foam Parts today for a free consultation or prototype request. Let us show you how our custom foam inserts can transform your packaging and protect your smart devices in transit.

FAQs

What types of smart devices benefit from custom foam inserts?

Any smart device that includes screens, electronics, or fragile components benefits from custom inserts. This includes smart plugs, thermostats, doorbells, speakers, security cameras, and more.

Can I customize foam colors and add my brand logo?

Yes, Custom Foam Parts offers color-matched foam and logo engraving options to enhance your brand’s visual identity during unboxing.

Are foam inserts environmentally friendly?

We offer a selection of recyclable and eco-friendly foam options. Talk to our design team about sustainable choices.

What is the typical turnaround time for custom inserts?

Depending on order size and complexity, we typically deliver within 7–14 business days.

Can I get a prototype before placing a bulk order?

Absolutely, we offer CAD prototypes and sample foam cuts so you can test fit and performance before committing to full-scale production.