Did you know that $1 billion worth of products get damaged during shipping every year in the U.S.? If you’re in the business of shipping goods, you understand how critical it is to make sure your products arrive safely and in perfect condition.

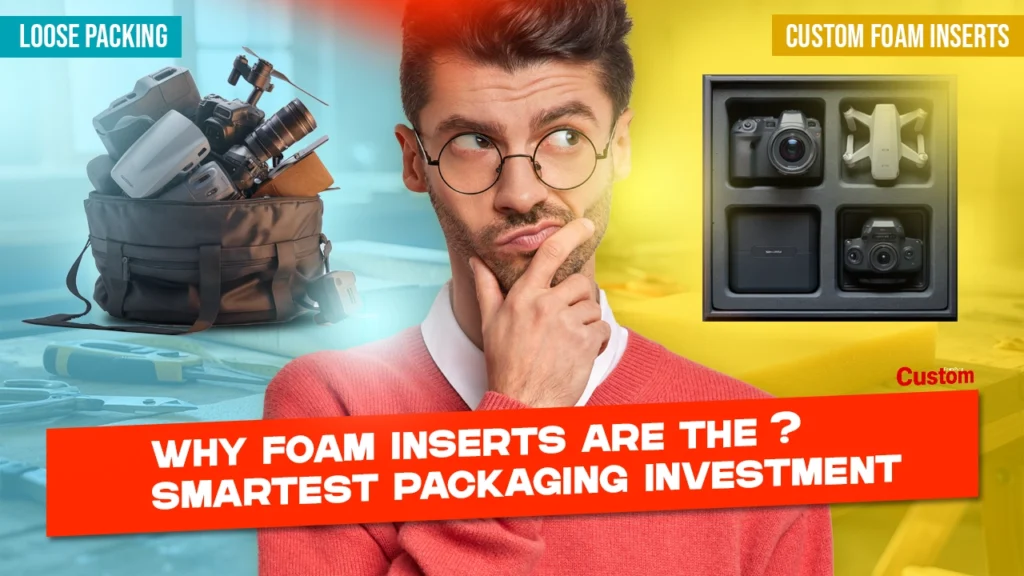

Poor packaging can lead to unhappy customers, costly returns, and even loss of business. But here’s the good news: foam inserts are an easy, affordable solution to prevent all of that.

Key Highlights

- Foam inserts cushion your products, ensuring they arrive safe and intact.

- They reduce returns and damages over time, making foam inserts a smart investment.

- Custom foam inserts to perfectly fit your products, improving packaging efficiency.

- Eco-friendly options offer both protection and sustainability.

They’re not just about keeping your items safe during transit; they help your business save money, improve your brand’s reputation, and ensure customer satisfaction. Let’s explore why foam inserts should be your go-to packaging solution.

Advantages of Foam Inserts

- Superior Shock & Vibration Resistance

- Custom Fit for Secure Product Placement

- Cost-Effective in the Long Run

- Eco-Friendly Biodegradable Options Available

- Versatile Protection Across Multiple Industries

- Durable & Reusable

Let’s discuss how:

Superior Product Protection

Foam inserts provide unmatched cushioning for fragile or high-value items, protecting them from bumps, drops, and vibrations. Your products arrive safely every time, giving you and your customers peace of mind.

Cost Savings in the Long Run

Foam inserts might cost a bit more upfront, but they’re an investment that pays off. By preventing damage, you’ll save on costly returns and claims. They also speed up your packing process—no more fumbling with bubble wrap or excess padding. Get products out the door faster, and keep your costs down in the long run.

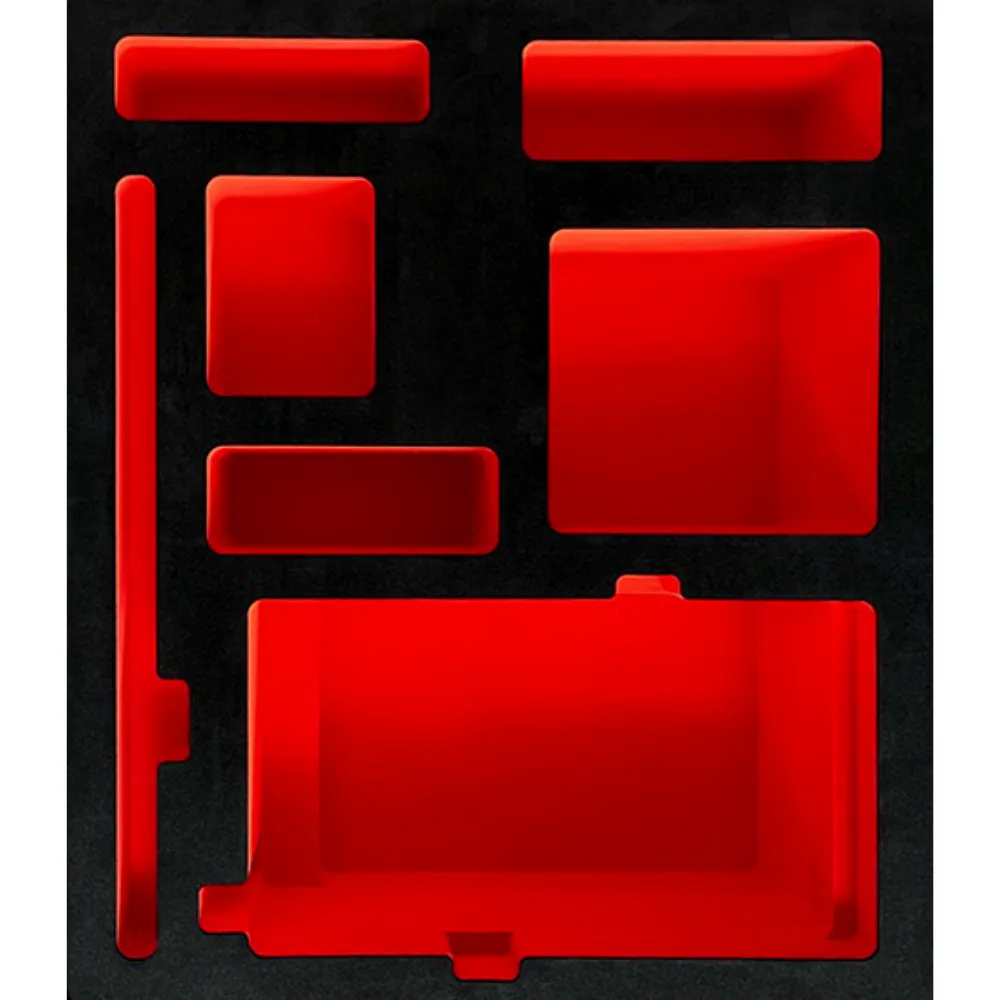

Customized Foam Inserts for Your Products

Not all products are the same, and your packaging shouldn’t be either. Custom Foam inserts are fully customizable to fit the exact shape and size of your products. This ensures your items stay securely in place during shipping, cutting down on waste and making your packing process smoother. Get the perfect fit, every time.

Shock and Vibration Resistance

Foam inserts absorb shocks and vibrations, providing extra protection for delicate or high-value items. Unlike bubble wrap or cardboard, foam handles the bumps and jolts of shipping, ensuring your products arrive safe and undamaged.

Eco-Friendly for a Greener Future

Your customers care about the environment, and so should you. Foam inserts now come in biodegradable and recyclable options, so you can protect your products and the planet. Choosing eco-friendly packaging is a win-win—reduce waste while keeping your brand aligned with sustainable values.

Enhanced Brand Perception

Packaging reflects your brand, and foam inserts elevate it with a premium, professional look. When products arrive safely, they leave a lasting impression, showcasing your commitment to quality and boosting customer loyalty.

Versatile Protection for Any Industry

From electronics to beauty products and automotive parts, foam inserts provide tailored protection for any type of shipment. Their versatility makes them a reliable solution across industries, ensuring your products stay secure and damage-free.

Durable Option

Foam inserts are designed for durability. They stand the test of time and can be reused again and again. That means fewer replacements and less waste, making them an even smarter investment. With foam inserts, you’re choosing long-term value and reliability.

The Perfect Custom Foam Inserts For Your Packaging Needs?

Comparing Foam Inserts to Other Packaging Materials

Foam Inserts vs. Bubble Wrap and Cardboard

So how do foam inserts stack up against the usual bubble wrap and cardboard? The difference is pretty clear. Foam inserts provide much better shock absorption. While bubble wrap can protect against light impacts, it doesn’t offer the customized fit that foam inserts do. And cardboard? While it’s sturdy, it doesn’t have the same cushioning effect as foam. Foam inserts also beat bubble wrap and cardboard in terms of ease of use. Bubble wrap needs to be cut, wrapped, and repositioned, while foam inserts just need to be placed in the box — no hassle, no mess.

Cost-Effectiveness Over Time

Although the initial cost of foam inserts might be higher than other materials, the long-term savings make them worth every penny. By reducing damage, lowering return rates, and improving operational efficiency, foam inserts pay for themselves. The value they offer in protecting your products and enhancing customer satisfaction is undeniable.

Industries That Benefit Most from Foam Inserts

Ensure Your Top-Notch Custom Foam Inserts For Packaging!

Addressing Common Misconceptions About Foam Inserts

“Foam Inserts Are Too Expensive”

It’s true that foam inserts have a higher upfront cost compared to bubble wrap or cardboard. However, when you factor in the long-term savings from fewer returns and damaged goods, foam inserts quickly prove to be a wise investment. The added protection ensures that your products reach customers safely, which means fewer complaints and a better reputation for your business.

“They’re Not Eco-Friendly”

There’s a common misconception that foam packaging is bad for the environment. But with biodegradable and recyclable foam options, you can have your cake and eat it too. Eco-friendly foam inserts offer the same level of protection as traditional foam but with the added benefit of sustainability.

Practical Tips for Choosing Foam Inserts

When choosing foam inserts, keep the following in mind:

- Material Type: Whether you need polyurethane, polyethylene, or an eco-friendly option, the material you choose will impact both the protection and sustainability of your packaging.

- Product Shape and Size: Make sure your foam inserts are custom-made to fit your products perfectly.

- Weight: Heavier items may require thicker foam inserts for optimal protection.

- Customization: Do you need custom branding or extra compartments? Foam inserts can be tailored to meet your specific needs.

Get Your Custom Designed Foam Inserts For Packaging Items

Conclusion

In conclusion, foam inserts provide unmatched protection, cost savings, and customizability for your packaging needs. Whether you’re shipping electronics, luxury goods, or industrial equipment, foam inserts are the packaging solution that ensures your products reach their destination safely and intact. Don’t wait for the next damaged shipment — invest in foam inserts today and experience the difference.

FAQs

Can foam inserts for presentation boxes be customised?

Yes, foam inserts can be customised to fit specific shapes, add branding, or create a premium unboxing experience.

Are foam inserts for boxes suitable for all product types?

Yes, foam inserts are versatile and can be designed to protect electronics, fragile items, or bulkier goods effectively.

Are gel or foam inserts better?

Foam inserts are better for packaging and shock absorption, while gel inserts provide superior comfort and pressure relief.

Which foam quality is best?

High-density foam is ideal for protection, while memory foam offers the best comfort and support for seating or cushions.

Why are foam inserts a popular choice for packaging?

Foam inserts offer superior shock absorption, custom fit, and protection, making them ideal for delicate and valuable products.

What materials are commonly used for foam inserts in packaging?

Polyurethane and polyethylene foams are popular for their durability and cushioning properties.

When should you use thick foam inserts?

Thick foam inserts are ideal for heavy or large items requiring extra cushioning to absorb shocks and vibrations.

Can thick foam inserts be cut to specific sizes?

Yes, thick foam inserts can be tailored to fit your product dimensions and packaging needs.

How do I choose the right foam for my cushion inserts?

Consider the foam’s density and firmness based on the intended use, such as seating, back support, or decorative purposes.

Are foam inserts for boxes eco-friendly in the USA?

Yes, many USA suppliers offer biodegradable or recyclable foam inserts to meet sustainable packaging needs.

How do I choose the right foam inserts for cushions?

Choosing the right foam insert depends on your specific needs, such as comfort, size, and durability. Consider density and firmness for the intended purpose.