The journey of custom foam inserts from factory to customer is a complex but fascinating process that blends advanced manufacturing technology, precision engineering, and customer-centric design. From material selection and CAD design to cutting, prototyping, and shipping, each step plays a vital role in ensuring that the final foam insert provides optimal protection, organization, and presentation for the end user’s product.

In this article, we’ll walk through every stage of the journey — from raw material sourcing to delivery — and explore how companies like Custom Foam Parts ensure quality, customization, and functionality throughout the entire process. We’ll also highlight how semantic SEO practices support businesses in making this process transparent and discoverable online.

Introduction to Custom Foam Inserts

Custom foam inserts are protective foam interiors designed specifically to fit and secure products within packaging. They’re commonly used in industries such as electronics, aerospace, medical, defense, tools, retail, and luxury goods. The purpose of these inserts is not just to protect fragile items during transit, but also to improve product presentation, ensure compliance, and enhance brand value.

Step 1: Understanding Customer Requirements

The journey begins with communication. The factory (like Custom Foam Parts) first consults with the client to understand the project scope. This includes:

- Product dimensions

- Weight and fragility

- Packaging type (cases, boxes, crates, etc.)

- Environmental conditions (temperature, moisture, vibration)

- Branding or visual presentation requirements

At this stage, customer needs are translated into design goals. Whether it’s a delicate medical device or a robust set of industrial tools, everything starts with a clear understanding of the application.

Keyword-rich example: “At Custom Foam Parts, our team collaborates with clients to develop precision foam packaging solutions tailored to their industry-specific challenges.”

Step 2: Material Selection – Choosing the Right Foam

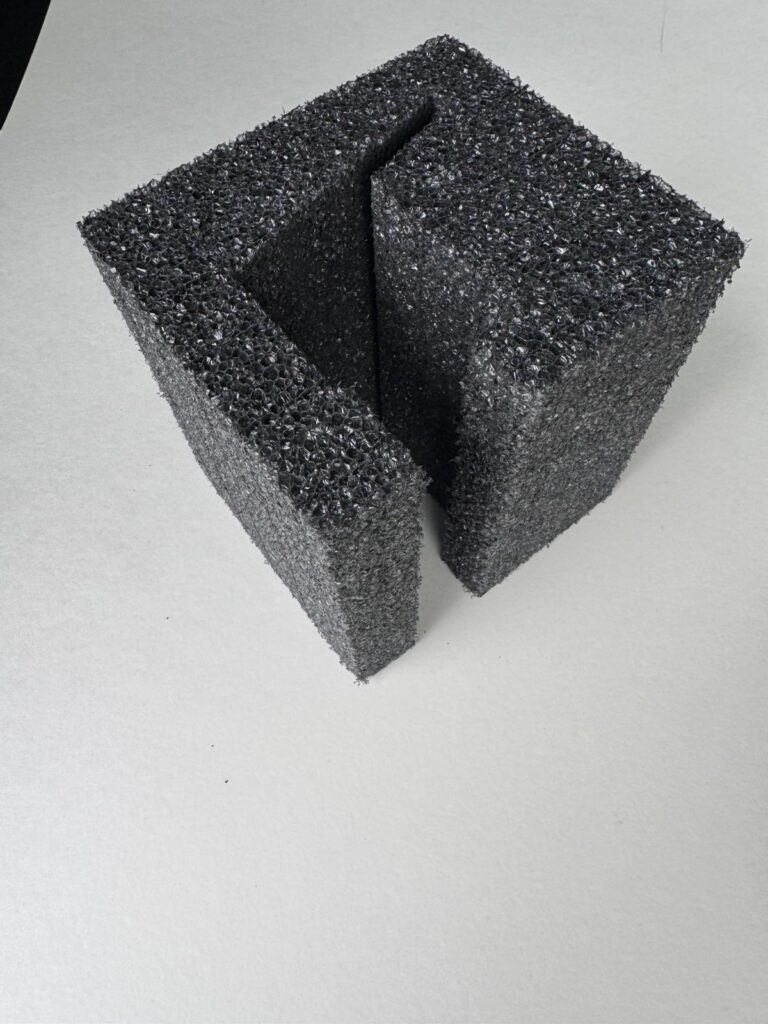

Not all foam is created equal. Selecting the right foam material is critical to both performance and cost-effectiveness. Popular foam types include:

- Polyethylene (PE) Foam: Dense, durable, excellent for tool and equipment protection.

- Polyurethane (PU) Foam: Softer, ideal for cushioning delicate items.

- EVA Foam: Flexible, impact-resistant, and often used in consumer electronics.

- Anti-static Foams: Essential for electronic components to prevent static discharge.

The factory’s material engineers test and match the foam type with the customer’s needs, considering factors like:

- Impact absorption

- Weight

- Reusability

- Aesthetic finish

Material selection also plays a role in sustainability. Eco-conscious customers might prefer recyclable or biodegradable foam.

Step 3: CAD Design and Engineering

Once requirements and materials are finalized, the design team develops a Computer-Aided Design (CAD) file. This digital blueprint outlines the exact dimensions, cutouts, and layering of the foam insert.

Key activities include:

- 3D scanning of the product

- Designing cutouts with appropriate tolerances

- Simulating packing and unpacking experience

- Ensuring ergonomic handling for end-users

Advanced CAD modeling allows for quick iterations, so any changes can be made before physical samples are produced. It also ensures compatibility with CNC routers, laser cutters, or waterjet machines during the manufacturing phase.

Step 4: Prototyping and Testing

Before mass production, a physical prototype is produced. This step ensures that:

- The product fits snugly in its cavity

- There’s no unnecessary movement inside the packaging

- The foam supports ease of use (e.g., product removal or insertion)

- Aesthetic and branding expectations are met

This prototype is often sent to the customer for approval or used in drop tests and vibration testing. If the design passes all tests, it’s cleared for production.

SEO tip: Including phrases like “custom foam insert prototyping,” “protective foam testing,” and “packaging mockup validation” helps improve visibility for engineering-focused users.

Step 5: Precision Manufacturing and Foam Cutting

Now comes the heart of the factory process: converting foam sheets into precision-engineered inserts.

Manufacturing techniques include:

CNC Routing

Automated, highly accurate cutting ideal for high-volume runs.

Water Jet Cutting

Uses high-pressure water streams to create intricate shapes.

Laser Cutting

Great for sharp edges and high-definition cuts.

Die Cutting

Best for mass production with consistent dimensions.

In this phase, layers may also be laminated to create multi-level trays, especially useful for kits, tools, or multi-component packaging. Manufacturers like Custom Foam Parts ensure tolerances are strictly maintained, as even small variations can affect product security or presentation.

Step 6: Quality Control and Inspection

Before shipping, the foam inserts go through multiple quality assurance steps:

Looking for surface defects or incorrect cutouts.

Ensuring precise fitting as per CAD specs.

Trying actual products in the foam cavity to verify alignment.

Especially for inserts used in shipping cases or field kits.

Quality assurance teams also check for compliance with industry-specific standards like ISO, ASTM, or MIL-SPEC.

Semantic SEO Tip: Using terms like “ISO-certified foam insert manufacturer” and “custom foam inspection process” helps boost trust and search relevance.

Step 7: Packing, Branding, and Shipping

Once approved, the foam inserts are packed — either independently or installed inside product packaging or custom cases. Additional options at this stage include:

- Branding elements (laser-etched logos, color matching)

- Lamination with felt or plastic

- Custom labeling and barcodes

- Kitting services (inserting the client’s product into the foam for final delivery)

The inserts are then packed for transit, ensuring they arrive in pristine condition. If shipping internationally, paperwork like customs declarations or material safety data sheets (MSDS) may be included.

Step 8: Final Delivery to the Customer

The last stage of the journey is delivery — either direct to the customer, to a third-party logistics center, or to the end user.

Key considerations at this stage include:

- Lead times

- Tracking and customer updates

- Post-delivery support

- Reorder options and repeatability

Many manufacturers offer just-in-time (JIT) shipping models to meet tight production schedules or seasonal demands. Companies like Custom Foam Parts also provide long-term packaging solutions, meaning customers can rely on consistent supply for recurring needs.

Why This Journey Matters to Your Business

Understanding the full journey from factory to customer gives businesses greater control over packaging quality, product protection, and customer satisfaction.

Key benefits of a streamlined custom foam insert process include:

- Reduced product damage in transit

- Improved unboxing experience

- Enhanced brand presentation

- Increased product longevity

- Cost-efficiency through optimized material use

For businesses in competitive markets, this packaging journey can be the difference between a professional delivery and a damaged, poorly presented product.

Conclusion

The journey of custom foam inserts from factory to customer is more than just manufacturing — it’s a finely tuned process that combines innovation, engineering, and client collaboration. From concept and material selection to precision cutting, inspection, and delivery, each phase ensures that the final product not only protects but elevates the items it holds.

Companies like Custom Foam Parts understand that high-quality custom foam packaging can leave a lasting impression and reduce logistical headaches. For businesses serious about protection, presentation, and performance — investing in a seamless foam insert journey is not just a choice, it’s a competitive advantage.