Custom foam inserts can save your money by protecting your items, lowering shipping costs, and helping products last longer. Many businesses waste money replacing damaged goods or handling returns. Foam inserts keep your items safe and snug, reducing risk and cutting down problems. Let’s walk through how this works.

What Are Custom Foam Inserts?

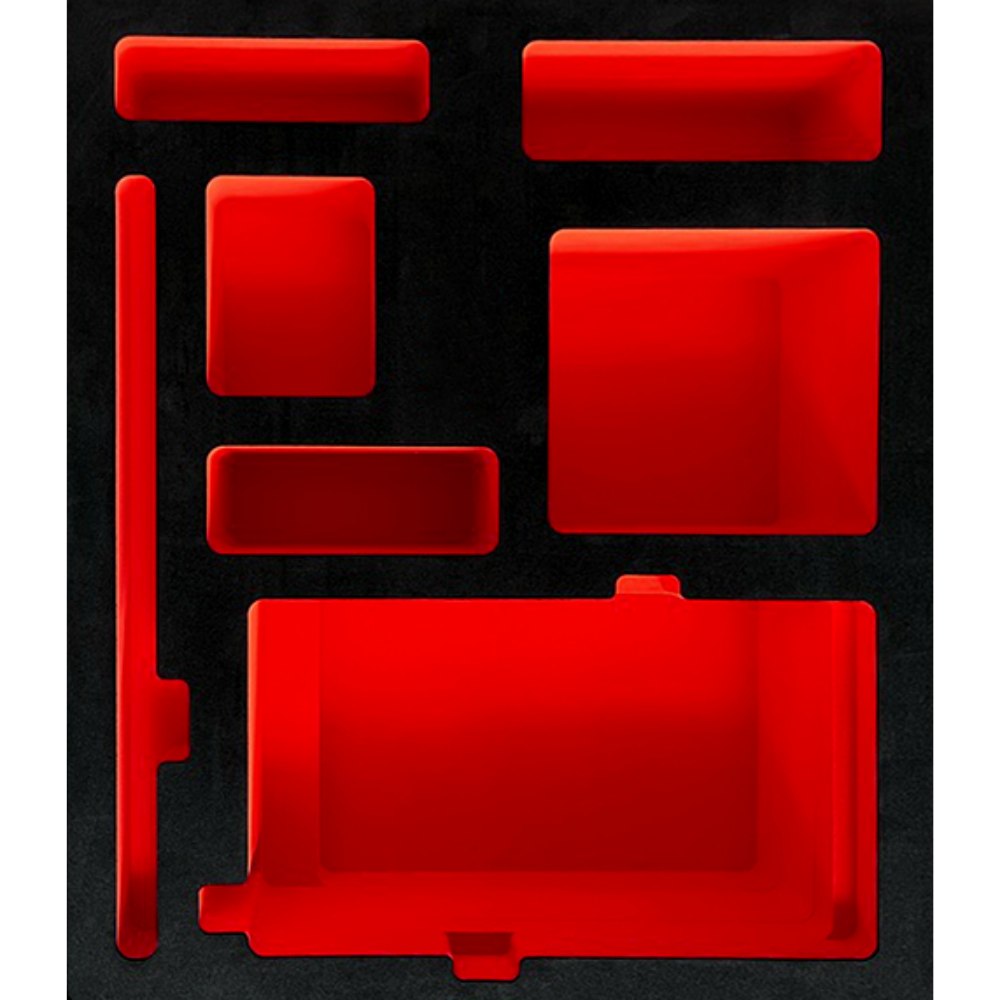

Custom foam inserts are specially cut pieces of foam made to fit your product. They are used to hold items tightly inside boxes, trays, or cases so nothing moves around.

Common foam types include:

- Polyethylene (PE) firm, good for tools or heavy gear

- Polyurethane (PU) soft and squishy, ideal for delicate items

- EVA foam slightly firm and flexible, great for display cases

Each type protects products from shocks, scratches, and pressure. Foam inserts can have clean cutouts that match your item’s exact shape. This stops it from sliding or bumping during travel.

Industries using foam inserts:

- Electronics and camera gear

- Jewelry and watches

- Medical devices

- Industrial tools

- Gift and luxury packaging

Instead of just using bubble wrap or cardboard, foam inserts are built for your item.

Why Damage Costs You More Than You Think

When something breaks during shipping, the cost isn’t just about the product.

You might also lose:

- Money from returns

- Shipping and packaging costs

- Customer trust

- Time spent fixing the problem

- Future sales

Even one damaged product can lead to a refund, an angry customer, and a negative review. According to industry research, 17% of packages get damaged in transit at least once.

If you sell fragile or high-value products, that risk is even greater. Over time, these small losses pile up.

How Foam Inserts Reduce Damage Risk

Foam inserts act like a soft, shaped seat for your product. Instead of rattling around, the item stays still.

Foam inserts:

- Stop movement inside the box

- Soak up shock from bumps and drops

- Prevent scratches from rubbing

- Add layers between parts or accessories

Let’s say you’re shipping a set of glass jars. Without foam, they might hit each other and crack. But with cut-to-fit foam around each jar, they stay in place—no cracks, no returns. Foam works like a cushion, absorbing the hit so your item doesn’t have to.

Saving on Shipping Costs with Lighter Packaging

Shipping companies charge based on:

- Weight

- Size of the package

That’s why heavy or bulky packaging costs more. Foam inserts are super light and can help reduce the overall size of the box.

Here’s how foam saves money:

- Takes up less space than other packing methods

- Weighs less than wood or plastic inserts

- Can be cut to fit tightly, avoiding empty space

If you’re shipping in bulk, this matters a lot. Even saving a few ounces or inches per box can cut thousands in yearly shipping costs.

Pro tip: Some foam inserts are made from closed-cell foam, which resists moisture and lasts longer, reducing replacements.

Longer Product Life Fewer Replacements

Protection doesn’t stop after shipping. Foam inserts keep products safe during storage too. You’ll find foam in:

- Camera or tool cases

- Medical trays

- Custom boxes for luxury goods

Why? Because foam prevents wear and tear from handling. It also keeps dust and dirt away. Imagine:

- A stethoscope stored in foam protected and clean

- A necklace in a custom foam slot no tangles or scratches

- A power tool in a foam-lined case no broken handles or loose screws

This means fewer damaged goods, fewer customer complaints, and fewer replacements.

How Custom Inserts Help Brand Image & Trust

Ever opened a box that looked messy? Maybe the product was wrapped in too much tape or sliding around inside. That doesn’t feel great. Now think of a box where everything fits neatly, looks clean, and stays in place. That builds trust.

Foam inserts help you:

This matters a lot if you sell online. First impressions happen during unboxing . Organized packaging leads to fewer returns and more repeat buyers.

Are Foam Inserts Really Worth It?

Foam inserts do cost a bit more upfront than plain boxes or plastic wrap. But over time, they save you money.

Here’s how:

- Less product damage fewer refunds

- Fewer complaints better reviews

- Tighter packaging cheaper shipping

- Better product care longer lifespan

For Example: Even a $2 foam insert can save a $40 item from being returned. Multiply that by hundreds or thousands of shipments, and the savings become clear.

Foam Inserts vs. Traditional Packaging

| Feature | Foam Inserts | Bubble Wrap / Paper | Plastic Trays |

|---|---|---|---|

| Protection Level | High | Low-Medium | Medium |

| Custom Fit | Yes | No | Limited |

| Reusability | Yes | No | Yes |

| Professional Look | High | Low | Medium |

| Cost (Per Item) | Medium | Low | High |

While foam may cost a bit more than bubble wrap, the extra protection and cleaner presentation often make it the smarter choice. And over time, fewer damages = lower total costs.

Best Use Cases That Show Real Savings

Jewelry Brand

A company shipped delicate gold earrings. Many arrived bent or tangled in pouches. They switched to EVA foam inserts shaped like the earrings. Complaints dropped by 80%, and return rates went down.

Tool Supplier

Tools like drill bits and wrenches were moving in boxes, getting scratched. With firm PE foam inserts, each tool had a perfect slot. Result: Products looked brand new even after shipping.

Camera Shop

A camera lens seller faced broken lens returns. They used high-density foam for protection. In 3 months, their damage reports dropped by 90%. These real examples show how simple foam packaging makes a big impact.

How to Choose the Right Custom Foam Insert

Not sure which foam to use? Ask yourself:

- How fragile is the item?

- How heavy is it?

- Is the product used once or stored often?

General tips:

- Use PE foam for heavy items

- Use PU foam for soft cushioning

- Use EVA foam for in-between needs

Also, talk to a foam specialist. At Custom Foam Parts, we help you pick the best option for your product and budget.

Where to Get Quality Custom Foam Inserts

Look for a provider that:

- Offers different foam types

- Can design inserts based on your product

- Has good reviews and customer service

- Delivers fast and accurately

Your packaging needs to work every time. That’s why Custom Foam Parts offers:

- Custom design

- Quick support

- Affordable pricing

Whether you ship 10 items or 10,000, we’ve got your packaging covered.

Final Thoughts

Custom foam inserts save your money by doing what matters most keeping your products safe. They lower damage rates, help with shipping, improve how your brand looks, and protect products during storage.

They’re easy to use, cost-effective, and make a big difference over time. If you’re ready to protect your profits, foam inserts are the way to go.

FAQs

What are custom foam inserts used for?

Custom foam inserts are used to protect products during shipping or storage by holding them snug in place.

Are foam inserts good for fragile items?

Yes, Foam inserts are perfect for glass , electronics, or anything that breaks easily.

How much do custom foam inserts cost?

Prices vary, but they usually cost between $1 to $5 per item. The savings from fewer damages often outweigh the cost.

Can foam inserts be reused?

Yes, Many foam inserts can last a long time, especially if kept dry and clean.

What types of foam are used for inserts?

PE (firm), PU (soft), and EVA (flexible) are common. The right one depends on your product’s needs.