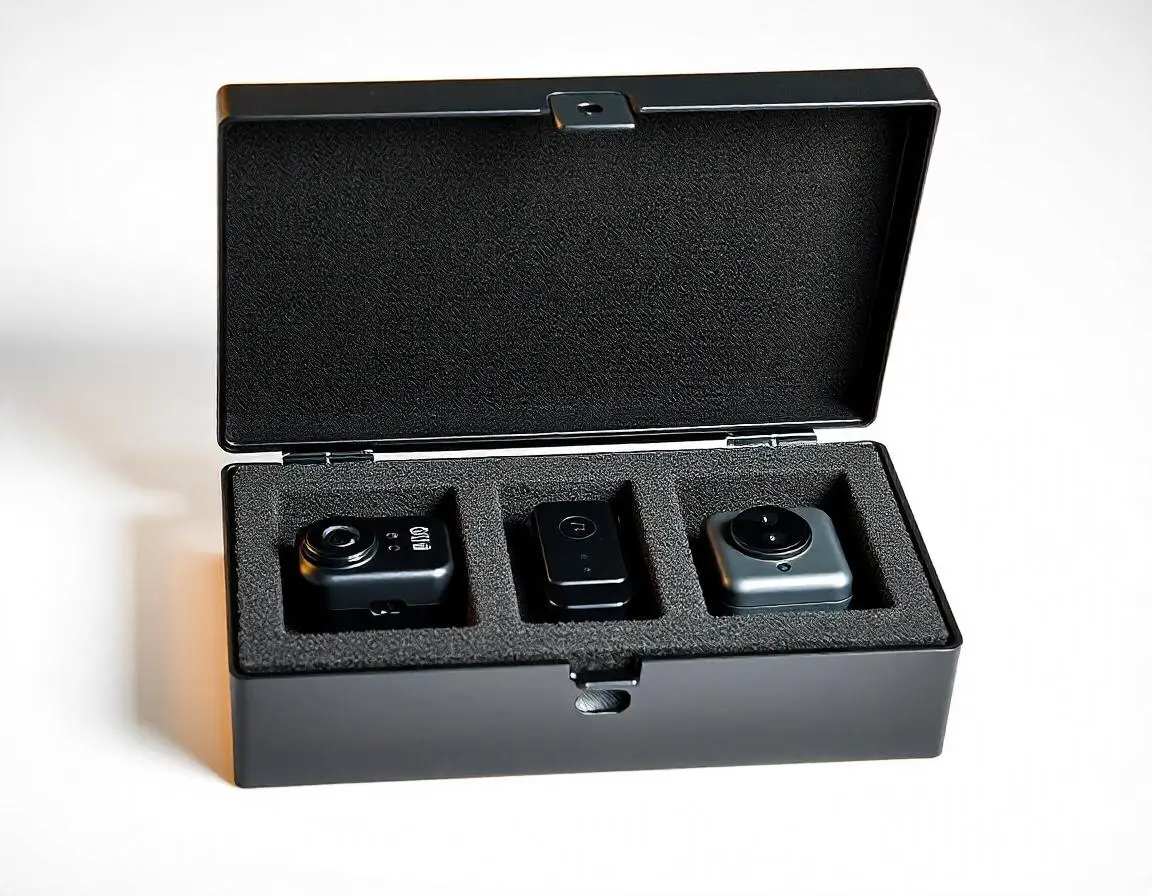

Custom foam inserts protect cameras and lenses by offering tailored cushioning that prevents scratches, absorbs shocks, and keeps your gear secure during travel, storage, or fieldwork. Whether you’re a professional photographer, filmmaker, or hobbyist, investing in high-quality foam inserts can dramatically extend the lifespan and performance of your expensive optical equipment.

At Custom Foam Parts, we understand that your camera gear isn’t just equipment—it’s a valuable asset. That’s why we specialize in crafting precision-cut custom foam inserts designed to fit your gear perfectly, offering unmatched protection against vibration, dust, impact, and environmental hazards.

Why Custom Foam Inserts Matter for Photography Gear

When transporting or storing fragile items like DSLR cameras, mirrorless bodies, action cams, or cinematic lenses, off-the-shelf solutions just don’t cut it. Generic foam dividers may shift, compress, or deteriorate over time, compromising the safety of your gear.

Here’s what sets custom foam apart:

- Tailored Fit: Every cavity is CNC-cut or laser-scanned to match the shape of your camera body or lens, eliminating unnecessary movement inside the case.

- Shock Absorption: The foam material absorbs external shocks from drops, bumps, and vibrations.

- Dust & Moisture Barrier: Closed-cell foam can act as a barrier against dust and moisture infiltration.

- Scratch-Free Storage: Your lenses and LCDs are cradled in soft yet firm material, preventing scratches and scuffs.

The Main Threats to Your Camera and Lens Safety

Understanding what you’re protecting your gear from helps you appreciate the value of custom foam inserts . Here are the top risks:

Impact Damage

Dropping a case or bag is more common than you’d think. Without proper padding, a fall could damage delicate sensors, lens elements, or mounts. That one mistake can cost hundreds—or even thousands—of dollars in repairs or replacements. Custom foam inserts are precision-engineered to absorb and distribute shock, protecting sensitive components and preventing gear from shifting during transit. Whether it’s a light bump or a serious drop, the foam acts as a first line of defense, significantly reducing the risk of breakage and ensuring your equipment arrives safely every time.

Vibration During Travel

Whether you’re on a bumpy road, in the overhead bin of a flight, or shooting in the field, small, repeated vibrations can affect your equipment over time. These micro-movements may not be noticeable immediately but can slowly degrade internal circuits, dislodge elements, and loosen fasteners. Custom foam inserts are designed with vibration-dampening properties, keeping your gear snug and secure no matter the environment. This added stability is crucial for professionals who travel frequently and need their equipment to remain calibrated and ready for action without unexpected wear and tear.

Dust and Debris

Even a small dust particle can scratch a lens or affect the performance of a camera sensor. Foam inserts minimize exposure by securing your gear in enclosed compartments. By filling every gap with custom-cut foam, you limit air circulation and reduce the entry of contaminants like sand, dirt, and moisture. This level of protection is especially important when working outdoors or in industrial or construction settings. Over time, a well-sealed case with foam inserts also helps extend the life of your equipment by preserving its optics, filters, and other delicate components from environmental hazards.

Poor Organization

Cluttered camera bags lead to misplaced items and accidental damage. Custom foam provides a systematic and visual inventory of your gear. Each piece of equipment has its designated spot, making it easier to set up quickly and ensuring nothing gets left behind on location. This type of organized storage also streamlines your workflow, helps identify missing or damaged items instantly, and presents a more professional image to clients. Whether you’re working in film production, photography, or videography, time saved searching for equipment is time better spent capturing the perfect shot.

Types of Foam Commonly Used in Camera Case Inserts

At Custom Foam Parts , we offer various foam options based on your application, aesthetic preference, and budget:

Polyethylene (PE) Foam

- Durable, firm, and excellent for heavy gear:PE foam’s dense and rigid structure makes it ideal for carrying heavy-duty equipment like cameras, lighting kits, or drone parts without compressing or losing shape during transport.

- Water-resistant and easy to clean:Its closed-cell construction repels moisture, dust, and grime, making it a great choice for outdoor shoots, marine environments, or any situation where cleanliness and dryness matter.

- Often used for camera cases with sharp edges or modular gear: Perfect for custom-cut layouts, PE foam holds gear with sharp corners securely in place, making it widely used in camera cases designed for interchangeable parts or modular systems.

Polyurethane (PU) Foam

- Softer, cushion-like feel:PU foam gently conforms to the shape of delicate items, offering a pillow-like effect that reduces pressure points and prevents scratches or cracks in sensitive camera and lens components.

- Ideal for delicate optics and glass lenses:The foam’s softness protects against abrasions and micro-vibrations, making it the preferred material for storing cinema lenses, glass filters, and precision optical components.

- Offers superior shock absorption for fragile items:PU foam absorbs impact energy efficiently, which is essential when transporting equipment in unstable or rough conditions such as air travel, field shoots, or courier services.

EVA Foam

- Combines firmness with flexibility

- Excellent for long-term protective packaging and aesthetics

- Common in luxury presentation cases for cameras or limited-edition lenses

How Custom Foam Inserts Are Made

Creating a truly protective insert isn’t guesswork—it’s engineering.

1. Equipment Mapping

We use high-precision scanning and CAD software to measure your exact equipment dimensions. This ensures that each foam cavity is designed to snugly fit every item, reducing movement and potential damage during transit. Our mapping process also allows for future modifications or additional components to be added without needing a complete redesign.2. Foam Selection

We help you choose the right density and type of foam depending on use-case, durability, and protection needs. Whether you’re shipping sensitive electronics, delicate optics, or heavy-duty industrial tools, we guide you through material options such as PE, PU, or EVA foams. We also take environmental conditions, frequency of use, and storage duration into account for maximum protection.

3. CNC or Waterjet Cutting

Advanced cutting methods ensure perfectly clean edges and contours that match your gear with precision. Our CNC routers and waterjet machines allow us to create custom cavities, rounded corners, bevels, and multi-depth layers with exceptional consistency. This level of accuracy enhances both the appearance and functional security of your packaging.

4. Final Assembly

Foam inserts are installed into cases or sent as modular trays, ready for use. Labels, finger pulls, or color coding can be added for enhanced usability. We also offer additional features like anti-static coatings, laminated tops, and laser engraving for branding or part identification. Every insert is thoroughly inspected before delivery to guarantee a perfect fit and finish.

Benefits of Using Custom Foam Inserts by Custom Foam Parts

A reliable pillow or protective support system ensures your gear and body remain safe, no matter how challenging the travel conditions are, giving you confidence and stress-free rest.

Reducing micro-damage and shock exposure helps extend the operational life of your camera equipment. Custom foam inserts add a layer of defense that absorbs vibrations during transport, minimizes impact-related wear, and protects against scratches, ensuring your gear performs at its best for years to come.

Presenting your gear in a neatly organized case enhances your brand image and simplifies setup on set or in the field. With tailored compartments and clean visual appeal, clients and collaborators instantly recognize your attention to detail and professionalism, setting a high standard for your work environment.

Organized layouts reduce packing/unpacking time and ensure you never forget a piece of gear again. Whether you’re traveling locally or internationally, custom foam inserts streamline your workflow, reduce stress, and make airport security checks easier by clearly displaying every item in your kit.

We offer logo engraving, color inserts, and layered foam for that extra touch of professionalism. Your packaging can reflect your unique brand identity while maintaining peak functionality ideal for creators, agencies, and production teams who want to leave a lasting impression on clients and partners.

Use Cases for Custom Foam Camera Inserts

- Freelance Photographers traveling with DSLR kits

- Cinematographers with multiple lenses and RED/ARRI cameras

- Drone Operators needing custom foam for controllers and payloads

- Production Houses organizing gear for multiple crew members

- Travel vloggers protecting compact kits on-the-go

No matter your role in the creative field, Custom Foam Parts can build a solution around your exact needs.

Why Choose Custom Foam Parts?

We’re more than a foam cutter—we’re your protection partner. Here’s what sets Custom Foam Parts apart:

- Fast turnaround times

- Expert foam engineers and designers

- Bulk and individual orders welcome

- Made in the USA with premium materials

- 100% Satisfaction Guarantee

Final Thoughts

Camera and lens protection is not something to compromise on. With the high cost of photography and videography equipment today, custom foam inserts are a smart investment that can save you from devastating losses. Whether you shoot weddings, wildlife, documentaries, or corporate content, having a secure, custom-fit case insert tailored to your gear gives you confidence on every shoot.

At Custom Foam Parts, we’ve helped thousands of creatives protect their equipment with foam solutions that are as functional as they are professional-looking. Let us design the perfect insert for your kit—get in touch today!

FAQs

Are custom foam inserts better than padded camera bags?

Yes. While padded bags offer general protection, custom foam inserts are tailor-made for your exact gear, preventing any movement or pressure points that can lead to damage.

Can you reuse foam inserts if I upgrade my camera or lenses?

It depends. If your new equipment is similar in size and shape, some foam inserts may still work. However, for maximum protection, we recommend updating your foam layout when your gear changes.

Do you offer waterproof or dustproof foam options?

Absolutely. We offer closed-cell foams like PE that are both waterproof and dust-resistant. We can also fit them into IP-rated hard cases upon request.

How long do custom foam inserts last?

With proper use, our foam inserts can last several years. PE and EVA foams are especially durable and resistant to wear and tear.

Can I get my logo or custom colors in the foam insert?

Yes, At Custom Foam Parts, we offer custom branding options including laser-engraved logos, color-coded layers, and printed case lids.