Custom foam inserts are the best way to protect, organize, and present your items whether you’re shipping products, storing tools, or packaging delicate equipment. They are made to fit your items exactly, giving them better safety, easier handling, and a cleaner look. If you’re wondering why so many people are using them now, here are 10 solid reasons to get started today.

Protects Fragile Items During Transit

One of the main reasons to use custom foam inserts is protection. When you’re moving or shipping items, they can easily get scratched, dented, or broken. Foam inserts act like a cushion. They absorb shocks caused by drops, bumps, or vibrations during transport.

Instead of your item moving around in a box filled with packing peanuts, custom foam gives it a perfect, snug fit. It’s like giving your item its own little seatbelt.

Real-world example: Think about shipping a high-end camera or drone. Even a small fall can damage sensitive lenses or parts. But when placed in a custom foam insert, each part has a secure space and stays protected even in rough handling.

Bonus tip: Use closed-cell foam for water resistance and extra durability during long shipments.

Reduces Product Damage & Return Rates

Every business wants happy customers. But when items arrive broken, returns and complaints pile up. This isn’t just frustrating it’s costly. Custom foam inserts lower return rates by reducing product damage. When your products stay safe, fewer customers ask for replacements or refunds. This saves time and money and also protects your reputation.

Stat to consider: Studies show that up to 30% of online returns are due to items being damaged during shipping. By simply upgrading your packaging with custom foam, you can avoid these losses and improve customer satisfaction.

Good for: E-commerce sellers, small businesses, retailers, and product-based brands.

Fits Any Shape or Size Precisely

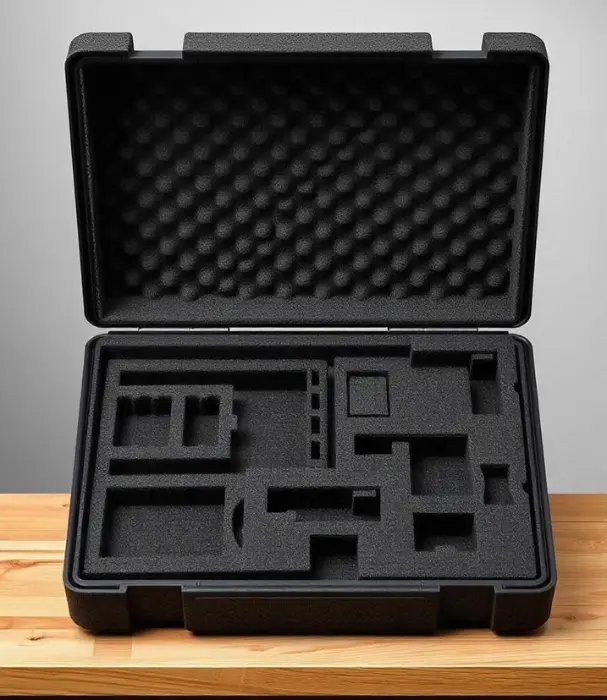

One of the best things about custom foam is that it’s cut to fit exactly what you need. From oddly shaped tools to fragile instruments, foam inserts can be made to hold any item snugly and securely.

This is done using CNC machines, laser cutters, or die-cut methods, depending on the complexity of the item. Whether it’s a small sensor or a big power tool, the foam surrounds it like a glove.

Why it matters: Generic foam or packing paper can’t give that same support. Loose items can shift, collide, and break. But with precision-fit foam, each item stays in its place.

Popular applications: Medical devices, drones, watches, knives, electronics, trophies.

Improves Presentation and Unboxing Experience

First impressions matter. When someone opens a box and sees a product perfectly placed in soft, custom-cut foam, it feels premium. The product looks cared for, valuable, and professional. This is a big deal in today’s world, where unboxing videos and customer experience can make or break a brand. Foam inserts add that “wow” factor especially for gifts, luxury items, or high-end tech.

Use in branding: Many jewelry companies use black or colored foam to enhance the look of their packaging. It keeps items safe and elevates the visual appeal.

Remember: People often judge your product by its packaging. Good foam design shows attention to detail.

Helps With Organized Storage & Inventory

Each slot is cut to fit a specific item, so you always know if something is missing. No more wasting time searching through cluttered drawers or messy toolboxes.

Industries that benefit: Mechanics, photographers, technicians, makeup artists, and warehouse workers all rely on custom foam to keep their gear sorted.

Efficiency tip: Organizing items in foam can reduce inventory check time by up to 40%, especially in busy work environments.

Saves Space and Makes Packing Easier

Custom foam inserts are designed to use space wisely. Since the foam is cut exactly to fit your item, there’s no wasted room. You can pack more efficiently whether you’re filling a toolbox, shipping box, or carrying case.

This helps in two big ways:

- Smaller boxes = lower shipping costs

- Easier packing = faster workflow

Also, because every item has its own spot, you won’t forget anything during packing or travel. It’s like a built-in checklist.

Bonus: Foam is lightweight, so it doesn’t add much to your shipping weight.

Reusable and Long-lasting Material

Unlike cardboard or bubble wrap, custom foam inserts are built to last. Many types of foam can be reused hundreds or even thousands of times.

Popular foam materials include:

strong, firm, water-resistant

soft, flexible, ideal for delicate items

smooth, durable, and stylish for display packaging

These foams are known for being tough and flexible. They keep their shape even after regular use. That means you don’t have to keep replacing your packaging .

Long-term use: Good foam inserts can last 5 to 10 years with normal handling.

Cost-effective Over Time

It’s true custom foam may cost more at first than cheap fillers like paper or peanuts. But over time, it actually saves you money.

Here’s how:

- Less product damage = fewer refunds

- Fewer returns = better profits

- Reusable packaging = no repeat buying

- Lower shipping costs = smaller boxes

- Time saved = fewer labor hours wasted

Think of it as a smart investment for your business. What you spend now, you save later in customer service, logistics, and reputation.

Real case: A tool manufacturer switched to custom foam and reduced annual packaging losses by 28% within the first year.

Used in Many Industries

Custom foam inserts are used across many industries and for good reason. They’re flexible, customizable, and helpful for anything that needs protection or presentation.

Here are just a few areas where foam inserts are essential:

Electronics

Protects laptops, tablets, circuit boards

Medical

Holds surgical tools, vials, instruments

Aerospace

Keeps sensors, gauges, and meters safe

Retail

Presents rings, watches, and glassware

Military & Defense

Stores tactical equipment safely

Photography

Keeps lenses and cameras protected

Construction

Organizes drills, screwdrivers, saws

Gaming & Hobby

Stores collectibles, miniatures, cards

If your industry relies on tools, parts, or premium goods custom foam inserts will likely fit right in.

Best Use Cases That Show Real Savings

Jewelry Brand

A company shipped delicate gold earrings. Many arrived bent or tangled in pouches. They switched to EVA foam inserts shaped like the earrings. Complaints dropped by 80%, and return rates went down.

Tool Supplier

Tools like drill bits and wrenches were moving in boxes, getting scratched. With firm PE foam inserts, each tool had a perfect slot. Result: Products looked brand new even after shipping.

Camera Shop

A camera lens seller faced broken lens returns. They used high-density foam for protection. In 3 months, their damage reports dropped by 90%. These real examples show how simple foam packaging makes a big impact.

Eco-Friendly Options Available

You might think foam is bad for the environment but today’s foam inserts can be eco-friendly too.

Many manufacturers now offer:

- Recyclable foam Can be reused or processed again

- Biodegradable foam Breaks down over time without leaving harmful waste

- Eco foam blends Made from plant-based materials

These are great for brands that want to reduce waste and appeal to eco-conscious customers. Green packaging is not just good for the Earth it’s also a selling point.

Tip: Add a “Recyclable Packaging” badge to your box if you use eco foam. Customers will notice.

Final Thoughts

There’s no doubt custom foam inserts are a smart choice. They help protect your items, organize your space, improve your packaging, and save you money in the long run. Whether you’re shipping fragile electronics, organizing expensive tools, or trying to impress your buyers with clean, pro packaging, Custom Foam Parts can help.

They’re flexible, reusable, and easy to customize. Plus, with eco-friendly options now available, you don’t have to choose between protection and the planet. So, if you’re tired of broken items, messy storage, or low-quality packaging it’s time to try something better. Start using custom foam inserts today. Your customers will thank you.

FAQs

What are custom foam inserts made of?

Custom foam inserts are usually made from PE (Polyethylene), PU (Polyurethane), or EVA foam. Each type offers different strengths—PE is tough, PU is soft, and EVA is sleek.

Can I use foam inserts for tools and electronics?

Yes. Foam inserts are great for both tools and electronics. You can cut them to match the exact shape of a wrench or a laptop. This keeps them safe and easy to carry.

Are foam inserts reusable?

Definitely. Most foam inserts are long-lasting and reusable. With good care, they can last for years without wearing out or losing their shape.

Can I get custom foam in different colors or styles?

Yes. Many companies offer custom colors, finishes, and layering. You can even print logos or add special coatings to match your brand.

Do foam inserts help reduce shipping costs?

Yes. Since foam inserts make packing more efficient, you can use smaller boxes and lighter materials. This often means cheaper shipping costs.