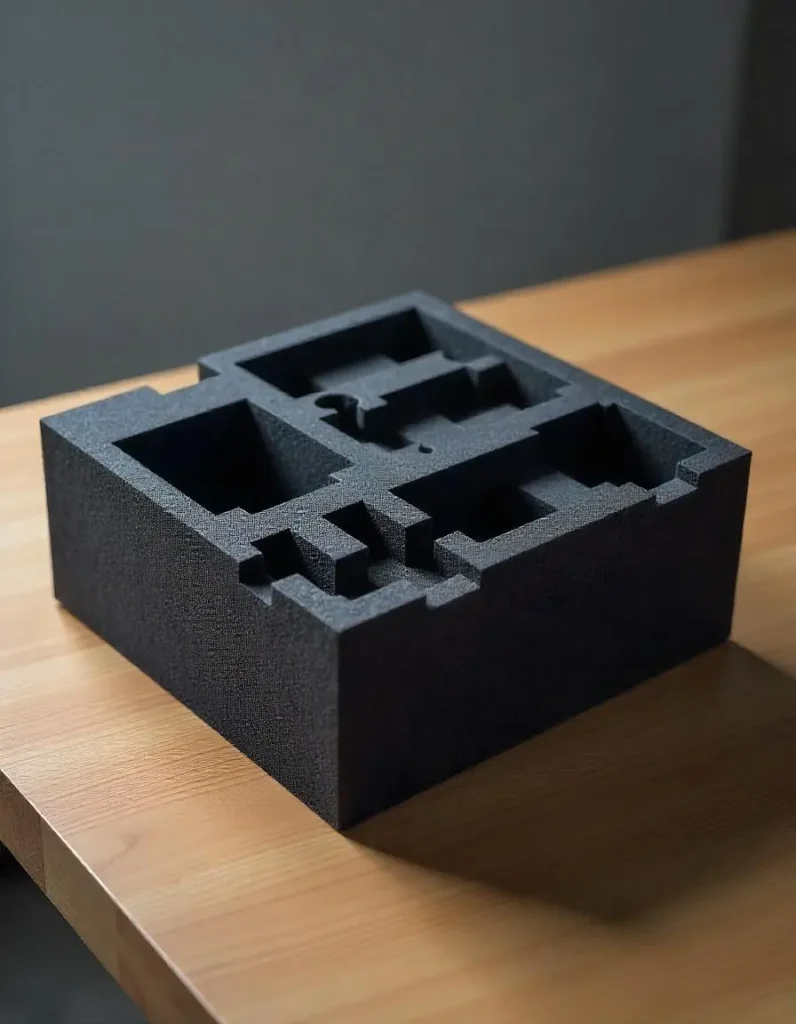

What Are Custom Foam Inserts?

Custom foam inserts are specially designed foam pieces that are cut to fit specific items. They provide a secure and cushioned enclosure inside a container, case, or box to protect products from damage due to impact, vibration, or mishandling. These inserts can be made from various foam materials including Polyethylene (PE), Polyurethane (PU), EVA foam, and anti-static foams, depending on the needs of the item being stored or transported.

Benefits include:

- Shock and impact absorption

- Improved product presentation

- Enhanced organization

- Custom branding options

- Long-term cost savings from reduced damages

Why Alabama Businesses Need Custom Foam Inserts

Alabama is home to a diverse range of industries including aerospace, automotive, defense, healthcare, electronics, and industrial manufacturing. These sectors often involve handling high-value or fragile equipment and tools that require maximum protection.

Custom Foam Parts help Alabama businesses:

- Protect sensitive and expensive equipment during transportation

- Ensure compliance with packaging standards in sectors like aerospace and defense

- Enhance professional appearance in product deliveries

- Reduce product returns and repairs

- Improve efficiency in storage and inventory management

The growing demand for e-commerce and precision logistics in Alabama further reinforces the need for reliable packaging solutions like foam inserts.

Industries Using Custom Foam Inserts in Alabama

Alabama’s aerospace industry relies on precise, shock-absorbing packaging for transporting tools, gauges, instruments, and high-value components. Foam inserts are custom-designed to fit each part exactly, minimizing movement and risk.

Custom foam inserts are widely used in medical device packaging. They provide hygienic, protective cushioning for surgical kits, diagnostic tools, and electronic medical devices.

From electronic components to delicate sensors and diagnostic equipment, custom foam packaging ensures secure delivery and proper storage across Alabama’s booming auto manufacturing hubs.

Electronics are sensitive to both static and impact. Anti-static and shock-resistant foam inserts are critical for shipping computer parts, sensors, and communication devices.

Jewelry, perfumes, and promotional gift boxes often use foam inserts to elevate the unboxing experience and prevent damage.

Custom foam tool inserts are common in manufacturing and construction sectors. These inserts help organize toolkits, increase safety, and speed up operations.

Types of Foam Materials for Custom Inserts

Polyethylene (PE)

A closed-cell, rigid foam ideal for heavy-duty protection. It offers high impact resistance and is often used in toolkits, equipment cases, and industrial packaging.

Polyurethane (PU)

Softer and more flexible than PE. PU foam is excellent for cushioning delicate items such as electronics or medical devices.

EVA Foam

Ethylene-vinyl acetate foam combines durability with flexibility and is water-resistant. It’s great for consumer goods, electronics, and sporting equipment.

Anti-static Foam

Designed to protect electronic devices from electrostatic discharge. Used in packaging for circuit boards, processors, and sensitive tech components.

| Foam Type | Key Properties | Common Uses |

| PE Foam | Rigid, durable, high impact resistance | Tools, machinery, heavy equipment |

| PU Foam | Soft, flexible, excellent cushioning | Medical tools, electronics |

| EVA Foam | Durable, water-resistant, flexible | Retail goods, consumer packaging |

| Anti-static | Static dissipative, protective | Electronics, circuit boards |

Customization Options & Capabilities

Custom foam inserts in Alabama come with a range of design and customization options:

Cutting Techniques

- CNC routing for precision

- Die-cutting for high-volume runs

- Laser cutting for detailed designs

Design Features

- Multiple color options for branding or coding

- Laminated or flocked finishes

- Engraved or screen-printed logos

- Modular tray systems for easy packing and unpacking

- Multi-layer inserts for complex products

Whether you’re packing a single item or assembling a product kit, foam inserts can be designed to match exact specifications and aesthetics.

Local Expertise Foam Insert Providers in Alabama

Alabama boasts a network of experienced foam fabrication companies and packaging experts who provide tailored solutions. Cities like Birmingham, Huntsville, Montgomery, and Mobile host several local suppliers specializing in foam cutting, CNC machining, and complete packaging solutions.

Working with local vendors ensures:

- Faster turnaround times

- Easier collaboration and prototyping

- Support for Alabama’s economy

- Reduced shipping costs and carbon footprint

How the Custom Foam Insert Process Works

Our step-by-step process makes it easy to get the perfect foam solution:

Consultation & Needs Analysis

Understanding your product, use-case, and environment requirementsDesign & Prototyping

Creating 2D/3D CAD models and physical samples for approval

Manufacturing

Using CNC or die-cutting machines to produce the inserts

Delivery & Integration

Foam inserts are delivered ready to be integrated into packaging, cases, or kitsThis end-to-end approach ensures that the final product not only fits perfectly but performs under real-world conditions.

Choosing the Right Custom Foam Partner in Alabama

Not all foam insert providers are equal. When selecting a partner, look for:

- Experience with your industry

- Range of foam materials and customization options

- In-house design and prototyping capabilities

- Quality control measures

- Positive client testimonials

Benefits of Using Custom Foam Inserts

Protects items from impact, abrasion, and vibration

Enhances customer perception and brand credibility

Keeps components and tools in place

Incorporate logos and colors to align with your identity

Fewer damaged returns, longer-lasting packaging

Why Choose Us

Whether you’re a manufacturer, medical supplier, or e-commerce business, investing in Custom Foam Parts is a smart move for product protection, organization, and branding. Alabama-based businesses can take advantage of local expertise, quick production times, and high-quality materials to get the foam solutions they need.

Request a Quote

Ready to enhance your packaging with our custom foam parts? Contact us today for a free quote. Our expert team is here to help you find the perfect solution tailored to your needs.

Frequently Asked Questions

What industries benefit most from custom foam inserts?

Industries such as aerospace, automotive, medical, electronics, defense, retail, and manufacturing benefit greatly from the enhanced protection and organization that custom foam inserts provide.

Can I get a sample before full production?

Yes. At Custom Foam Parts, we offer design mockups and prototype samples so you can approve the fit and functionality before full-scale production begins.

What foam material is best for my product?

It depends on your application. PE foam is ideal for heavy tools and equipment, PU foam is excellent for delicate items, and anti-static foam is essential for electronics.

Are your foam inserts environmentally friendly?

We offer sustainable and recyclable foam options upon request. Let us know if eco-friendliness is a priority for your packaging solution.

How long does the custom foam insert process take?

Typical turnaround time ranges from 1 to 3 weeks depending on complexity, volume, and material availability. We provide faster timelines for urgent projects.

Can foam inserts be branded with my company logo?

Absolutely. We offer printing, engraving, and color options to reflect your brand identity directly on the foam.

Do you ship foam inserts outside Alabama?

Yes. While we serve many Alabama-based clients, Custom Foam Parts can ship nationwide and even internationally.

What’s the minimum order quantity (MOQ)?

Our MOQs vary based on material and design complexity, but we do accommodate small batch orders as well as large-scale production.

What if I need to redesign or update my foam insert in the future?

No problem. We keep design files on record and can quickly update, scale, or modify inserts based on your evolving needs.

How do I get started with Custom Foam Parts?

Simply contact us through our website or call our team. We’ll schedule a consultation to understand your needs and begin the custom design process.