Why Choose Custom Foam Inserts in Pennsylvania?

Ultimate Protection During Shipping

Custom foam inserts absorb shock, reduce vibration, and prevent damage during transportation. This is crucial for high-value and fragile items like electronics, medical tools, and sensitive instruments.

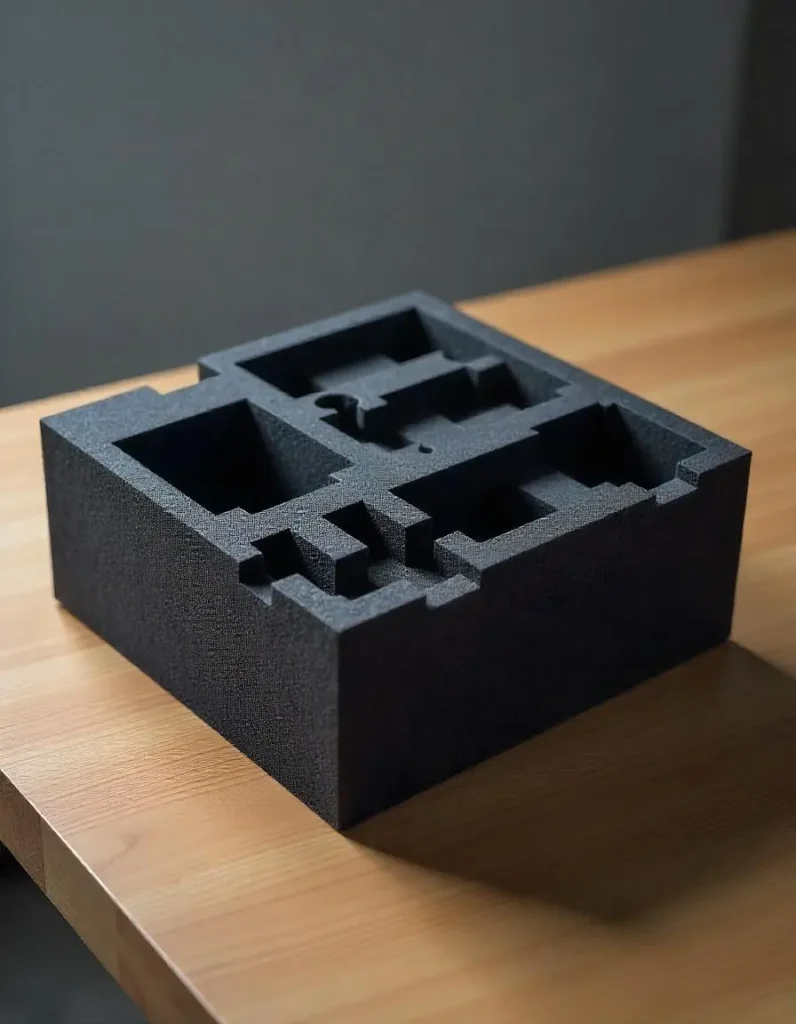

Tailored Fit for Every Product

Unlike generic packaging, our foam inserts are CNC-cut or die-cut to match the exact shape and dimensions of your items. This ensures a snug, secure fit and eliminates movement inside the box.

Professional Product Presentation

Well-designed foam inserts enhance unboxing experiences. They keep components neatly arranged and visually appealing — ideal for high-end retail, tradeshow samples, or B2B product demos.

Reusable & Eco-Friendly

We offer long-lasting, recyclable foam options that can be reused multiple times. It’s an environmentally conscious way to maintain packaging quality while reducing waste.

Our Foam Insert Capabilities in Pennsylvania

Our production facility caters to businesses across Pennsylvania, offering custom design and manufacturing services for a wide range of foam insert needs:

- Custom Foam Cutting Pennsylvania: CNC and laser cutting for accurate, scalable foam insert production.

- Die-Cut Foam Inserts: Ideal for high-volume orders needing cost-effective, repeatable designs.

- Protective Foam Inserts: For shipping electronics, tools, instruments, and sensitive goods.

- Foam Kitting & Assembly: We provide full packaging solutions including trays, dividers, and labeling.

Types of Foam Materials We Offer

We help you choose the right foam based on product fragility, use case, and environmental conditions.

🔹 EVA Foam Inserts

Durable, high-density foam with excellent shock absorption. Ideal for heavy or high-value equipment.

🔹 Polyethylene (PE) Foam

Lightweight yet strong, PE foam is commonly used for tool cases and industrial packaging.

🔹 Anti-Static & Conductive Foam

Specialty foam that protects electronic components from static discharge.

🔹 High-Density vs. Low-Density Options

We offer a wide range of densities to suit everything from soft-touch presentation cases to rigid industrial crates.

Industries We Serve Across Pennsylvania

Our foam inserts are used by manufacturers and professionals in:

Packaging for avionics, sensors, and mechanical parts.

Foam trays for surgical kits, diagnostic devices, and pharmaceutical containers.

Protection for circuit boards, CPUs, robotics components.

Tool cases, engine parts, and hardware.

Luxury goods, cosmetics, and electronic gadgets.

Customization Options for Foam Inserts

We offer various enhancements to align with your brand and packaging needs:

Add company logos or product info directly on the foam.

Use different foam colors for visual organization.

Multi-level inserts for kits with numerous components.

For products that require maximum protection.

When you need high-quality foam inserts, our craftsmanship and technology deliver peace of mind.

Why Choose Us

- Quick Turnaround: From design to delivery, we work fast to meet your deadlines.

- USA-Based Manufacturing: All inserts are made in the USA with local support.

- Precision Engineering: Advanced CAD/CAM tools and CNC machinery for tight tolerances.

- Small Runs & Bulk Orders: Whether you need 10 or 10,000 pieces, we deliver with consistency.

Our Design & Manufacturing Process

We provide complete end-to-end services for custom foam parts in New Hampshire:

Consultation

Tell us your product details and packaging goals.3D Modeling

We provide digital mockups and layout designs.Prototype & Sample Approval

From small batches to mass production.

Cutting & Assembly

Using CNC routing, die cutting, and lamination.

Quality Control

Every insert undergoes strict inspection.Real-World Use Cases in Pennsylvania

Customized PU foam trays reduced damage claims by 75%.

Medical Equipment Supplier – Houston, TX

Die-cut PE foam helped reduce packaging time by 40%.

Tool Manufacturer – Detroit, MI

EVA foam cases used for transporting sensitive equipment securely.

Defense Contractor – Arlington, VA

Anti-static foam inserts used in packaging for AI components.

Robotics Startup – Silicon Valley, CA

What Makes Our Foam Inserts Stand Out?

Getting started is simple. Here’s how to order:

- Durability: Made from high-grade materials for long-term use.

- Precision Fit: Every insert is cut to exact product specs.

- Aesthetic Value: Clean, professional look that enhances brand value.

- Eco-Friendly Options: Recyclable materials available on request.

Get a Quote

Need protective packaging tailored to your exact product needs? Contact Custom Foam Parts today for a consultation. Whether you’re in manufacturing, healthcare, or electronics, we’ll engineer the perfect foam insert for your application. Businesses across Pennsylvania trust us for durable, cost-effective, and precision-made custom foam inserts.

Frequently Asked Questions

What is the lead time for a custom foam insert order in Pennsylvania?

Most orders are completed within 7–10 business days after design approval.

Can you produce foam inserts for unusually shaped or fragile products?

Absolutely. We specialize in precision-fit foam for custom shapes.

What type of foam is best for tools vs. electronics?

Tools typically use PE foam; electronics often need anti-static PU or EVA foam.

Do you offer nationwide delivery?

Yes, we ship to all U.S. states with fast, secure delivery.

Are your foam inserts environmentally friendly?

We offer recyclable and reusable foam types on request.