Why Choose Custom Foam Inserts?

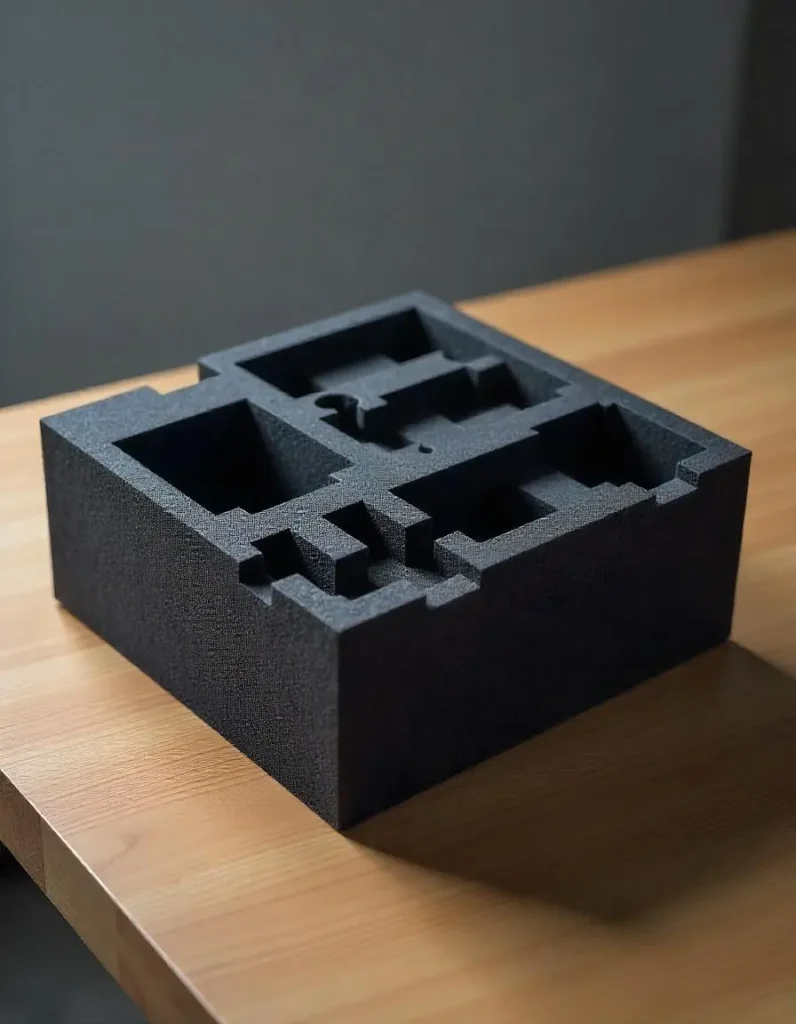

Custom foam inserts are far more than just packaging material. They are engineered solutions designed to:

- Absorb impact and reduce vibration during transport

- Organize items within toolboxes, cases, or packaging systems

- Improve product presentation and brand value

- Shield from moisture, dust, static, and scratches

- Fit precisely within containers for optimal safety

With high-quality foam inserts, you’re not only investing in protection.You’re elevating your entire logistics and customer experience.

Industries We Serve Across West Virginia

From Charleston to Morgantown, we work with clients in multiple industries that require reliable, custom protective solutions. Our foam inserts are designed to meet the specialized needs of:

Foam cavities designed for surgical tools, diagnostic kits, and delicate equipment.

High-impact, military-grade foam to protect critical components and tools.

Sleek, branded packaging inserts that enhance product display and reduce shipping damage.

Customized foam trays and cases for parts, tools, and assemblies.

Shock-absorbing inserts for cameras, drones, sensors, and more.

Rugged foam layouts for tools, measuring devices, and mobile equipment.

Our team understands the unique challenges of each sector and delivers custom foam solutions that meet those challenges head-on.

Foam Inserts for Packaging in West Virginia

Packaging isn’t just a box—it’s the first impression and a protective shell for your product. Our Foam Inserts for Packaging West Virginia services ensure:

- Products stay stationary and secure during shipment

- Packaging absorbs shock and vibration

- Brand presentation is consistent and professional

- Inserts are fully customized to match your product dimensions

We provide custom foam inserts for boxes, shipping containers, retail display units, and more—each designed to protect and impress.

Custom Foam Cutting: Precision You Can Trust

No two products are the same—and neither are our foam inserts. Our Custom Foam Cutting West Virginia services ensure your product fits perfectly into its protective shell. We utilize:

- CNC Routing: Delivers complex, accurate cavities with repeatable precision. Ideal for prototyping and small-batch runs.

- Waterjet Cutting: Clean cuts through thick or dense foam for a polished finish and intricate designs.

- Die Cutting: Fast and consistent production for repetitive shapes and high-volume orders.

Whether you need a one-time batch or scalable production, our cutting technology ensures every piece meets exact standards.

Types of Foam Inserts Available in West Virginia

We offer a wide range of foam types to meet different application requirements. From dense industrial foam to soft cushioning materials, we have it all.

🔹 EVA Foam Inserts

EVA (Ethylene Vinyl Acetate) foam is known for its durability, flexibility, and resistance to water and chemicals. Applications include:

- Tool storage

- Electronics protection

- Retail display trays

EVA foam is perfect for rugged or outdoor applications that require resilience and visual appeal.

🔹 PU Foam Inserts

Polyurethane (PU) foam is lightweight, soft, and cost-effective—great for delicate or lightweight products.

- Medical device packaging

- Camera and lens storage

- Cosmetics and glassware

It’s also great for providing multiple cushioning layers and can be die-cut for consistency.

🔹 Die-Cut Foam Inserts

Need scalable, high-volume packaging solutions? Our Die-Cut Foam Inserts West Virginia are ideal for:

- Assembly lines

- Inventory kits

- Retail or promotional packaging

Each insert maintains dimensional accuracy and repeatability while reducing per-unit cost.

Protective Foam Inserts: Your Safety Partner

Our Protective Foam Inserts West Virginia service goes beyond basic cushioning. We engineer foam to meet specialized protection needs:

- Anti-static foam for sensitive electronics

- Fire-retardant foam for high-heat environments

- Closed-cell foam for water and dust resistance

- Vibration isolation

- Impact zones

- Weight distribution

These features ensure that your products—whether fragile or mission-critical—arrive in perfect condition.

Our Custom Foam Solutions

Our foam manufacturing process is built around your needs. We provide full-service Custom Foam Solutions West Virginia, including:

Consultation

We gather your specifications, dimensions, and intended use.CAD Design

Our design engineers create 3D layouts for accurate fit and form.

Prototyping

A sample is produced for testing and feedback.

Production

We scale production with CNC, die-cutting, or waterjet methods.

Delivery

Foam inserts are shipped across West Virginia with on-time delivery guarantees.We handle both short-run and large-scale orders with the same dedication to quality and turnaround speed.

Why Businesses in West Virginia Trust Us

We are your go-to source for custom foam parts in New Hampshire because:

Our experienced engineers and designers ensure that every insert we create performs flawlessly in real-world conditions.

Serving All Major Cities in West Virginia

We proudly serve clients throughout West Virginia, including:

Whether you’re in a major city or a surrounding rural area, we provide fast shipping, local support, and expert consultation.

Get Started

Don’t leave your product’s safety or presentation to chance. Upgrade to precision-engineered Custom Foam Inserts in West Virginia. Our team is ready to help you with tailored designs, fast quotes, and high-quality production.

FAQs

What are custom foam inserts used for?

They protect, organize, and present products by fitting precisely into containers or cases.

Which industries use foam inserts the most in West Virginia?

Industries such as healthcare, aerospace, retail, and manufacturing benefit greatly from custom foam inserts.

What types of foam do you offer?

We offer EVA, PU, polyethylene, anti-static, and fire-retardant foams.

Can you cut foam to fit custom dimensions or complex shapes?

Yes, we use CNC, die-cutting, and waterjet cutting for exact, custom fits.

How quickly can I get my custom foam inserts delivered?

Lead times vary by order size, but we offer fast production and delivery throughout West Virginia.